Water Treatment for the Food and Beverage Sector

Clean, safe, and compliant water systems for food production environments

In food and beverage manufacturing, water quality isn’t just a process consideration—it’s a fundamental safety requirement. Whether it’s used as an ingredient, for cleaning, or in packaging and utilities, every drop of water that enters your facility must meet strict hygiene, quality, and regulatory standards.

AllWater Technologies designs and supplies food and beverage water treatment systems tailored to the exacting needs of this sector. From high-performance filtration and disinfection systems to bespoke hygienic process water configurations, our solutions help safeguard product integrity, reduce risk, and ensure full compliance with food-grade regulations.

We support facilities ranging from dairy and brewing plants to meat processing, canning, and bottling operations, offering scalable systems that integrate seamlessly into your existing processes.

Engineered for Food-Safe Compliance

Food and beverage producers face increasing regulatory scrutiny when it comes to water usage, hygiene, and discharge. AllWater systems are engineered to meet industry-specific requirements and help customers maintain operational excellence across:

- BRCGS Food Safety Standards

- FSA hygiene regulations and local authority requirements

- HACCP water safety planning

- WRAS-approved components and materials

- ISO and environmental permitting frameworks

- BRCGS Food Safety Standards

Our hygienic water systems are built using food-grade materials, sanitary connections, and validated disinfection technologies to minimise microbial risks and protect your brand reputation.

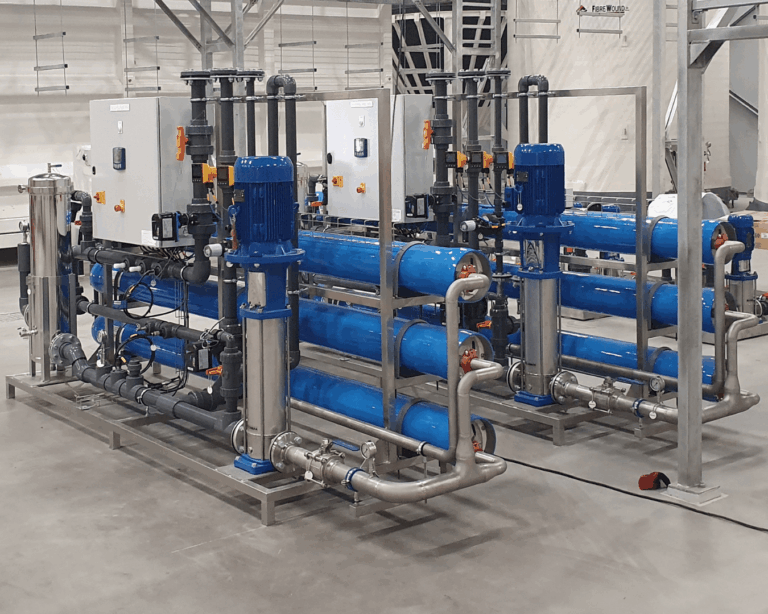

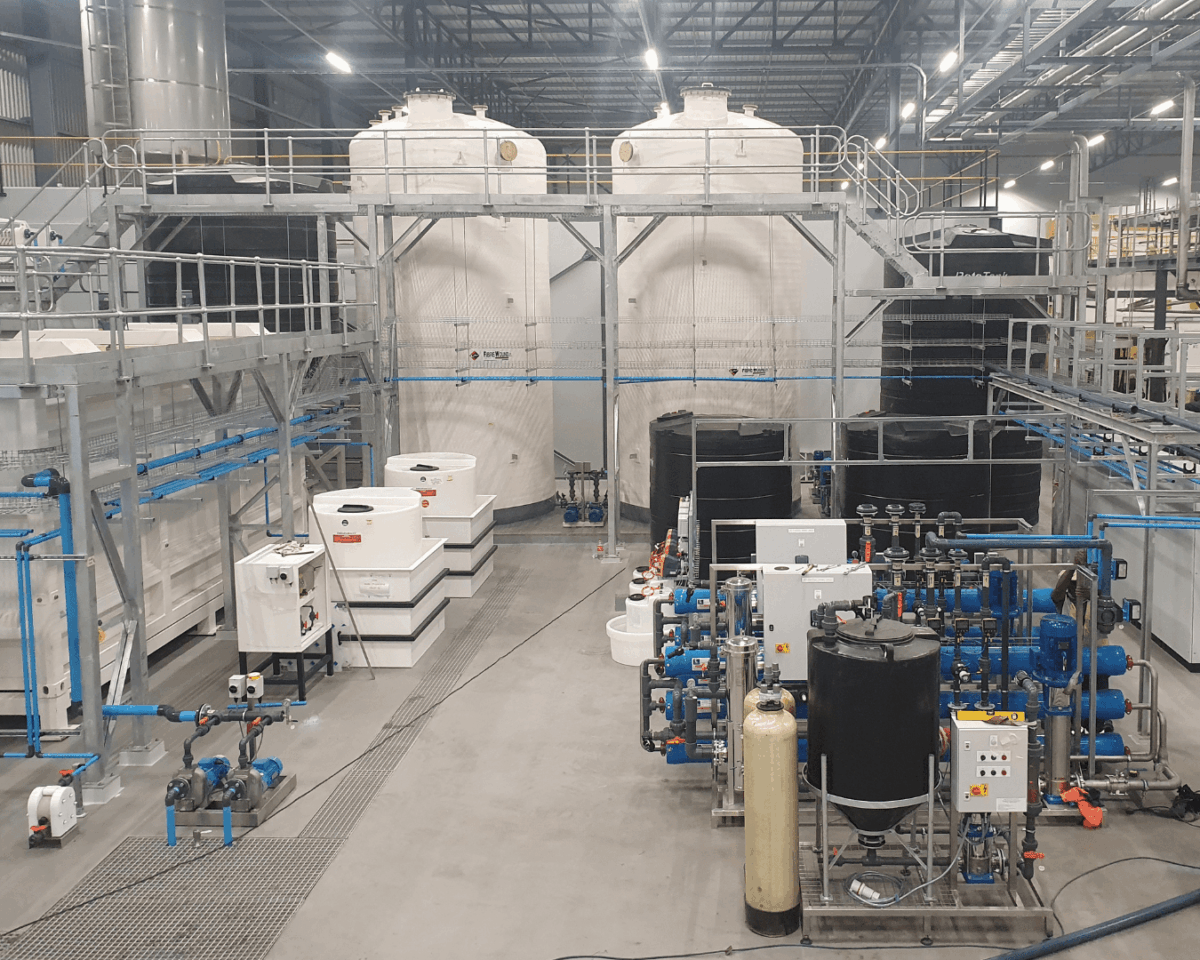

Complete Process Water Solutions

We offer comprehensive treatment systems for every stage of food and beverage production. Whether you’re improving water for ingredient use or protecting downstream equipment, our modular systems are designed for reliability and consistency.

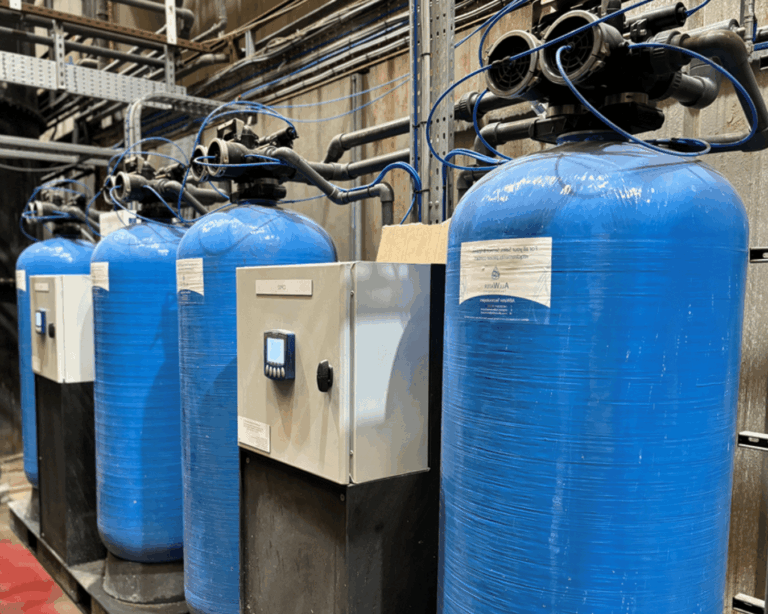

Water Purification and Filtration

Remove sediments, chlorine, bacteria, and dissolved contaminants with robust multi-stage purification systems.

Technologies include:

- Beverage water filtration using carbon, cartridge, and multimedia filters

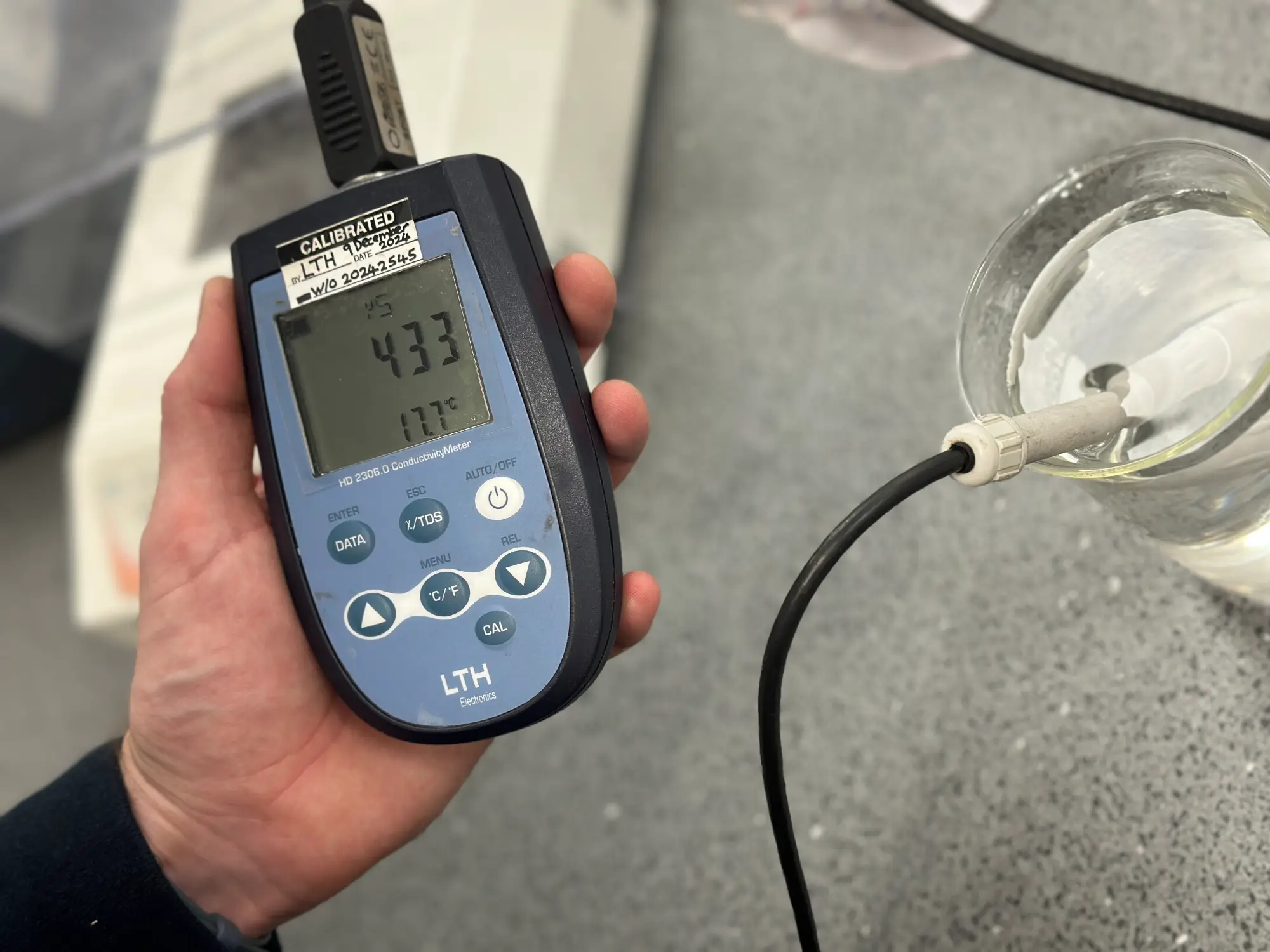

- Reverse osmosis (RO) for high-purity ingredient or process water

- Ultrafiltration (UF) for microbial control and suspended solids removal

- Deionisation and softening for boiler feed and CIP systems

All systems are fully configurable and available in compact or high-volume formats for small facilities or large-scale operations.

UV Disinfection and Chemical Dosing

We integrate UV sterilisation units and automated dosing systems to ensure water remains safe and biologically stable.

Benefits include:

- Chlorine-free disinfection with no residual taste or odour

- Elimination of bacteria, viruses, and algae

- Reduced risk of biofilm formation in pipework

- Minimal operator intervention with automatic control

Systems are selected based on your flow rate, process criticality, and required log reduction values.

Boiler and Utility Water Treatment

Steam and heating systems play a vital role in cooking, sterilising, and packaging. Poor water quality can cause scale, corrosion, and process interruptions. Our boiler feed systems include:

- Softening and RO for scaling prevention

- Dosing systems for oxygen scavenging and pH control

- Condensate return polishing for system protection

Each unit is tailored to your pressure, temperature, and throughput needs.

Effluent and Wastewater Treatment

Discharge from food production can contain fats, starches, sugars, and cleaning agents—all of which must be treated before discharge to drain or the environment.

We offer wastewater systems that support compliance with consent-to-discharge limits, including:

- pH correction and balancing

- Grease traps and DAF units

- Biological treatment and sludge dewatering

- Outfall monitoring systems

Recycling systems can also be integrated for low-risk reuse applications such as washdown or cooling.

Our support includes

Telephone & remote diagnostics for rapid fault identification

System troubleshooting and root cause analysis

Planned service visits tailored to your production schedule

Guidance on optimisation, upgrades and retrofit options

Ongoing training and user support post-installation

On-site engineering support from qualified specialists

Hygienic Design as Standard

Every AllWater system for food and beverage use is built around key hygienic principles:

- Sanitary pipework and fittings (tri-clamp, dairy pipe, etc.)

- 316L stainless steel construction where appropriate

- Minimised dead legs and accessible designs for cleaning

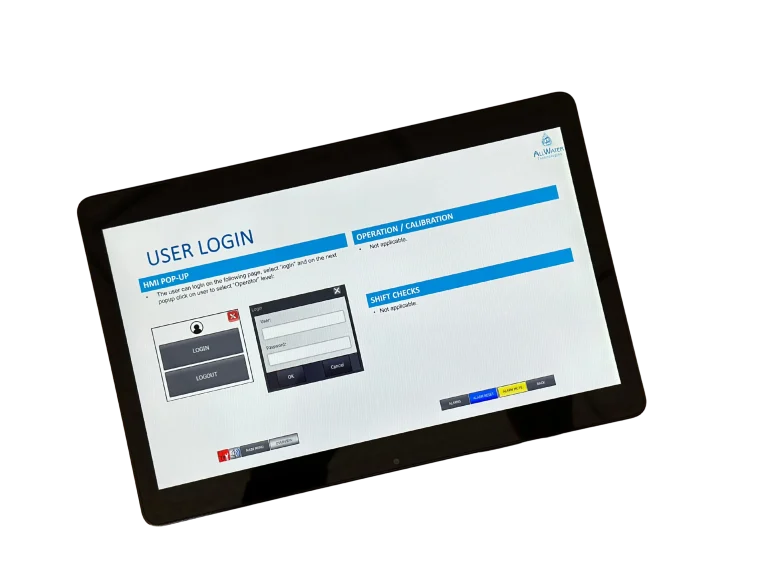

- Inline instrumentation and control for automated monitoring

We collaborate with site engineers, food safety teams, and external consultants to ensure hygienic best practice is followed at every stage.

Serving a Wide Range of Applications

Our clients in the food and beverage sector span all scales of operation and product types. We support:

- Bottled water and soft drink producers

- Dairy and cheese processing facilities

- Meat, poultry, and seafood plants

- Bakeries and confectionery manufacturers

- Breweries, distilleries, and wineries

- Canning, bottling, and ready-meal producers

Whether you’re expanding a line, modernising ageing equipment, or building a new site, AllWater provides systems that match your water quality needs with operational simplicity.

Full Lifecycle Support

We offer more than just equipment. Every system is backed by engineering expertise and ongoing support, including:

- Site surveys and specification guidance

- System design, build, and factory testing

- Commissioning and hygiene validation

- Multi-year service contracts

- Emergency response and spares supply

- Operator training and compliance support

We also offer trial systems and pilot equipment for feasibility studies or seasonal increases in production demand.

Why Choose AllWater?

- Food-grade, WRAS-compliant systems designed for hygiene and reliability

- Full design, supply, install and maintain capability

- Proven track record across UK food and drink manufacturing

- Custom solutions for ingredient water, CIP, steam, and wastewater

- Ongoing technical and compliance support

ISO 9001:2015 certified quality management

Committed to Excellence

Ready to Improve Your Water Treatment Process?

Whether you need to meet new standards, reduce costs, or improve product consistency, AllWater can help. We’ll assess your current setup and provide a tailored, no-obligation proposal aligned to your production goals and food safety requirements.

"We have been very happy with AllWater’s professionalism and response times when we have needed help with the plant. The staff are all very helpful and knowledgeable and we are very satisfied with the service provided."

Jamie Davies

Turnspeed"We needed a DI plant that is capable of producing the processing water to serve our Chemical Process lines twelve rinse tanks, 24 hrs a day, 7 days a week at a max of 20.00 μS/cm. The water plant is now consistently cleaning the water to 1.00 μS/cm."

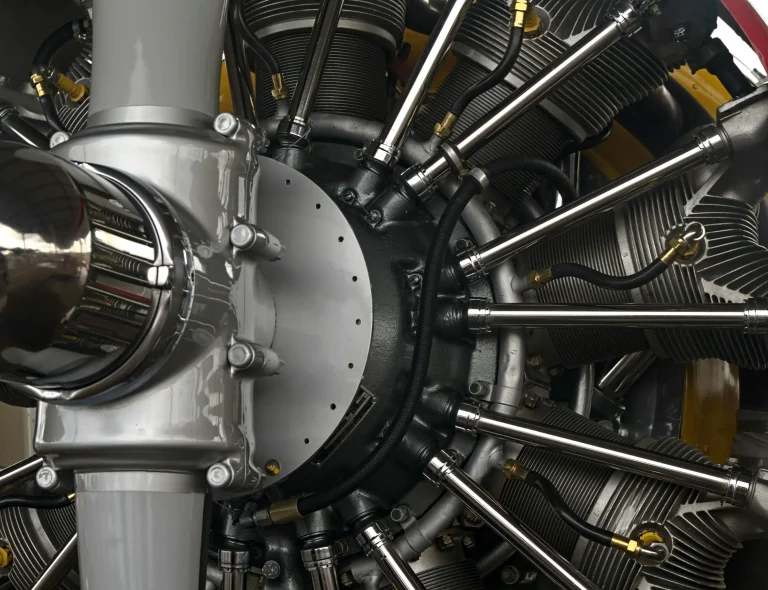

Steve Silk MBE

Marshall Aerospace"We have built a good relationship with AllWater and continue to enjoy service contracts with them. They know what they’re doing and we’re always happy with their service"

Andy Best

Production Director - Vertik-Al"AllWater Technologies installed their pure water system in our premises to replace our old system which went into retirement. The level of service and maintenance that AllWater are giving us will ensure that we get the quality of product and the length of service we are looking for out of our plant. Their level of service is excellent."

John Malone

excel gs ltd"Thank you for all your support. I have to say that I am really impressed with All Water approach to provide a really good service. Thank you again."

Radu Vitanescu

Liberty Engineering"AllWater have provided great service, specialist advice and an effective waste water treatment solution for our site."

Paul Pearcy

Warburtons"AllWater have always delivered us a great service and are equally competent maintaining existing kit or installing new. They’re friendly and reliable and, perhaps most importantly, trustworthy."

Phil Parkinson

Joseph Holt"AWT professional service allows our site to run with minimal downtime when unplanned breakdowns happen. AWT service is invaluable in maintaining our production lines throughout."

Adam Cook

Qsil"The person was very polite and explained everything in detail. Report was typed and easy to understand."

Richard Fox

London and Brighton Plating"We are more than satisfied with the level of service we receive from everyone at AWT. Excellent work, Thank you!"

Daniel Holden

Karas Plating"AllWater Technologies provide an exceptional level of knowledge and support, and we cannot fault their service and commitment. The team consistently exceed expectations and although others may offer a cheaper alternative, we have every confidence that they could not offer better!"

Eric Allen

Albumedix LTD"By using AWT we know that our plant and equipment is being maintained to the highest standard using the expertise and knowledge that we find second to none. When issues arise it is paramount that we can resolve these issues promptly; AWT are always there to support us."

Allen Staunton

Creganna Medical"Using All Water Technologies has been a breath of fresh air. Their attentive service from the first call through to delivery completion, has made the management of our water treatment plant very easy indeed. We wash over 2.5 million items of tableware for the event industry every year, working at some of the UK’s most prestigious events, so having peace of mind over our washing operation is essential. I would recommend AWT to anyone’"

Joe Nisbet

Jongor Hire"AWT offered Rimex a bespoke solution to our water softening and storage requirements. They took charge and managed the project efficiently and effectively from the very beginning. I am delighted with the outcome and I will continue to use AWT for preventative maintenance and any other future projects."

Daniel Meakin

Rimex Metals"All went very well with the plant being well finished, installation being of a high standard and all works being completed on time and to specification."

Dom Oughton

Optimum"We’ve been working with the AllWater team for eight years and they have always been attentive to our needs. AllWater redesigned our borehole system, transforming it into a robust and reliable plant whilst helping us improve water recovery and achieve significant water savings. We’ve depended on this system and their technical guidance for many years now and will continue to do so. Their work helps give us confidence and they are a partner we know we can trust."

Stephen Shields

Huntapac - Technical & Sustainability Director"At Butcombe, AllWater Technologies have been servicing the water treatment systems in our brewery for over 10 years. They are always at hand when we need them and all very friendly to deal with, and callouts are always made in a very timely manner. They have kept our beer flowing having never let us down. A great company with a quality reliable service."

Simon Court

Brewer - Butcombe Brewing Co.Ready for Support?

Unsure how to optimise water treatment for your industry? Our team is here to help. We’ll assess your requirements, design a solution, and provide the quality, reliability, and service you deserve. Reach out to discuss how we can help you achieve your operational goals.

Get in touch today to discuss your requirements.

Let’s keep your systems running at their best.

Frequently Asked Questions (FAQ)

Water used as an ingredient must meet strict microbiological and chemical standards. Process and utility water may have different requirements depending on the application. We help you define and achieve the right specification.

Yes. We design systems with cleanability in mind, using sanitary components and smooth internal finishes to allow safe CIP or SIP where needed.

We can advise on water-related hazards and control points, and supply monitoring instruments to support a compliant HACCP plan.

Yes. All systems are built to meet WRAS, BRCGS, and local environmental discharge requirements. Documentation and operator training are provided as standard.

Yes. In some cases, treated effluent can be reused for washdown, irrigation or cooling. We help assess the feasibility and provide compliant solutions.

Water Treatment Case Studies

Explore our case studies to see how AllWater Technologies has partnered with clients across various industries to design and deliver tailored water treatment solutions. Each project highlights our commitment to meeting exacting standards, solving unique challenges, and optimising water management processes to help our clients achieve their operational goals. Discover how our expertise and dedication to quality have made a real difference for businesses just like yours.

A Handful of our Valued Clients

Get in Touch with AllWater Technologies

We’re here to help with all your water treatment needs. Whether you have questions about our services, want to discuss a project, or need support, our team is ready to assist you. Fill out the form for general enquiries, or you are welcome to email direct or give us a call.

AllWater House

Unit 2,

Cheddar Business Park,

Wedmore Road,

Cheddar

BS27 3EB

Opening hours

Mon-Fri: 08:30-17:30 (GMT)