Industrial Water Tanks

Durable, Compliant Water Storage for Industrial and Commercial Applications

AllWater Technologies supplies a wide range of industrial water tanks engineered for high-performance water treatment, storage, and monitoring applications. From standard storage tanks to custom WRAS approved tanks and specialist v-notch designs, our solutions are tailored for safe, efficient, and regulation-compliant use across industrial and commercial sectors.

Whether you’re looking for a chemical dosing tank, clean water reservoir, or flow monitoring setup, we provide robust tank systems with fully integrated pipework, control, and access features.

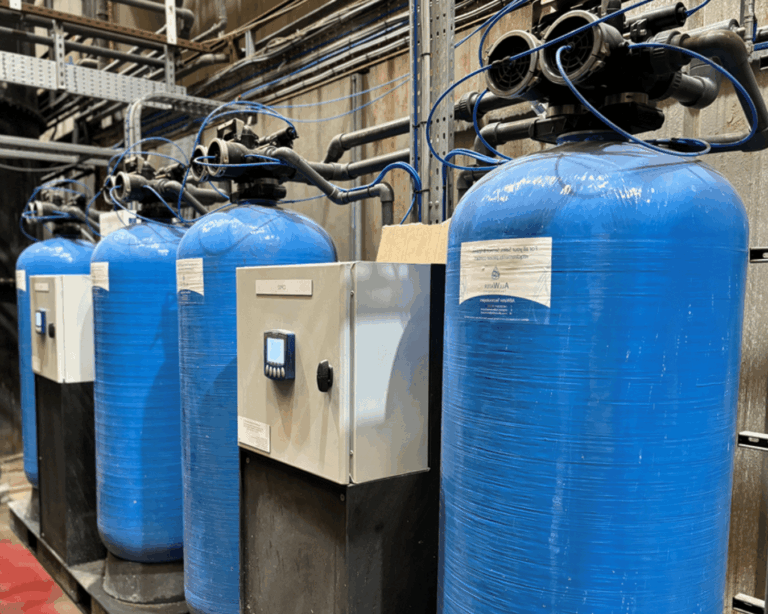

Water Storage Tanks

Clean Water and Process Water Storage

Our standard water storage tanks are ideal for holding process water, RO permeate, softened water, and treated effluent. Manufactured from high-grade polyethylene or polypropylene, these tanks offer excellent chemical resistance and mechanical strength.

Key Features:

- Capacities: Available from 50 to 30,000+ litres

- Materials: PE, PP, PVC, or GRP depending on application

- Fittings: Threaded, flanged, or bespoke connections

- Mounting options: Freestanding, bunded, skid-mounted, or on steel frames

- Covers: Removable lids or sealed tops for hygiene and safety

Colour options: Natural, black, or UV-stabilised materials to suit contents and conditions

All tanks are designed for long service life and minimal maintenance. We also supply compatible level sensors, overflow alarms, insulation jackets, and sight glasses as part of a complete tank package.

Our support includes

Telephone & remote diagnostics for rapid fault identification

System troubleshooting and root cause analysis

Planned service visits tailored to your production schedule

Guidance on optimisation, upgrades and retrofit options

Ongoing training and user support post-installation

On-site engineering support from qualified specialists

WRAS Approved Tanks

For applications where contact with potable water is required, we supply WRAS approved tanks manufactured to meet UK Water Regulations Advisory Scheme (WRAS) standards. These tanks are commonly used in:

- Potable water distribution systems

- RO permeate and DI water storage

- Boiler feed tanks

- Domestic and commercial building services

WRAS approval guarantees that all wetted materials are suitable for use with drinking water and will not introduce taste, odour, or contamination. These tanks are usually supplied with certified fittings, seals, and gaskets and can be provided with documentation for regulatory sign-off.

V-Notch Tanks

Outfall Monitoring and Flow Measurement

V-notch tanks are specialist units designed for open-channel effluent flow monitoring, typically used to support compliance with Environmental Agency ‘consent to discharge’ licenses. These tanks feature a calibrated V-shaped weir that allows for accurate measurement of flow rate based on the water height above the notch.

V-Notch Tank Features:

- Integrated V-weir: Typically 90-degree or 60-degree angle for volumetric flow calculation

- Sample access: Open channel design allows for manual or automated sampling

- Monitoring integration: Compatible with pH probes, flow sensors, temperature monitors, and data loggers

- Construction: Manufactured from corrosion-resistant polypropylene or GRP

- Sizes available: From 300 to 3000 litres, or custom-built

These tanks are essential in industries where discharge limits must be carefully monitored and recorded, including food processing, manufacturing, and laboratories.

Tank Materials and Customisation

AllWater supplies tanks in a wide range of materials to suit different chemical, temperature, and mechanical requirements:

| Material | Properties | Typical Use |

| Polyethylene (PE) | Good chemical resistance, lightweight | General-purpose water storage |

| Polypropylene (PP) | Higher temperature tolerance | Chemical dosing and pH tanks |

| PVC | Resistant to acids and alkalis | Laboratory and fume applications |

| GRP | Strong and corrosion resistant | Outdoor or bunded tanks |

| Stainless steel | Hygienic, high temperature and pressure | Food/pharma or clean-in-place |

Custom fabrication services are available for unusual tank sizes, restricted space, or specialised fittings. Our team will assist with design, specification, and documentation.

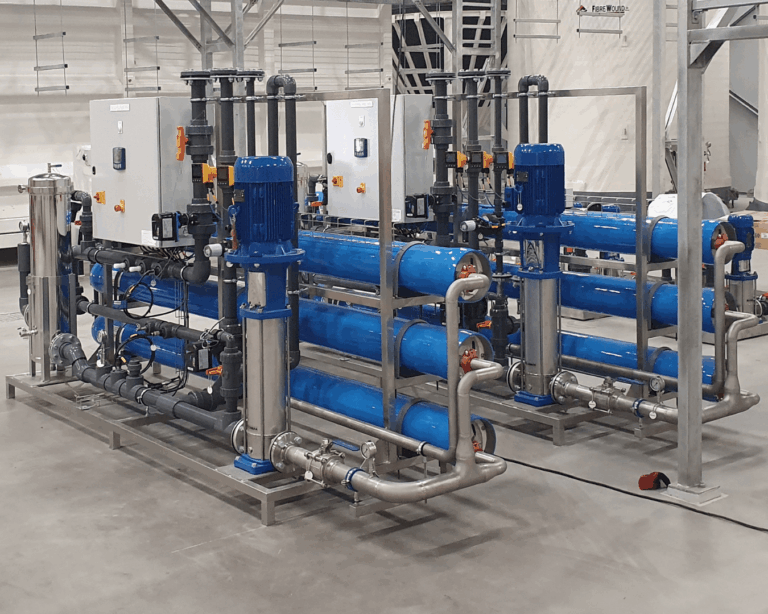

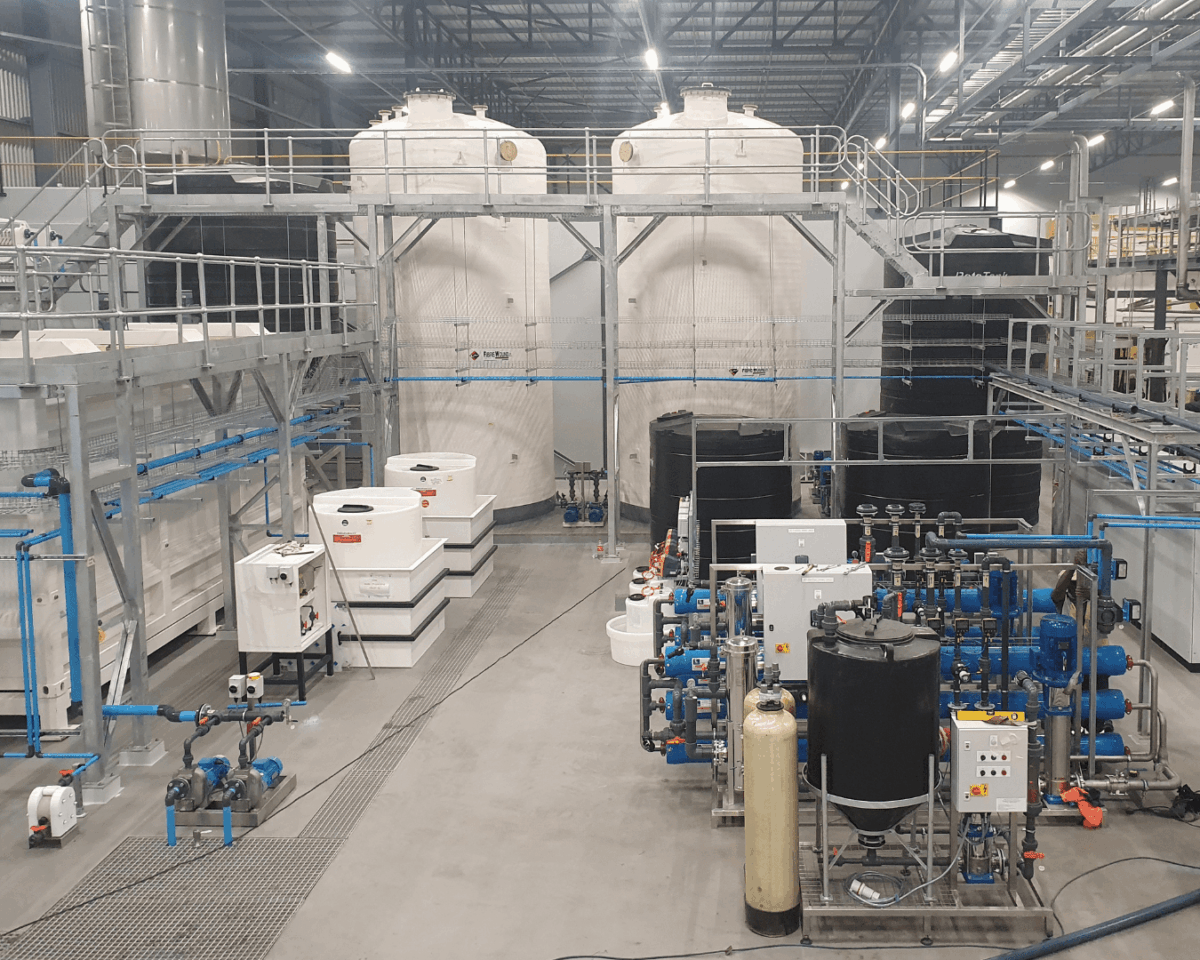

Integrated Tank Systems

Many of our tanks are supplied as part of a complete system. This includes:

- Bunds and containment trays to meet spill regulations

- Level control and alarms (float switches, ultrasonic sensors, pressure transducers)

- Inlet/outlet pipework (PVC, ABS, stainless steel)

- Heaters and insulation for frost protection or process needs

- Agitators or mixers for chemical dosing tanks

- Pump integration for automatic refill or discharge

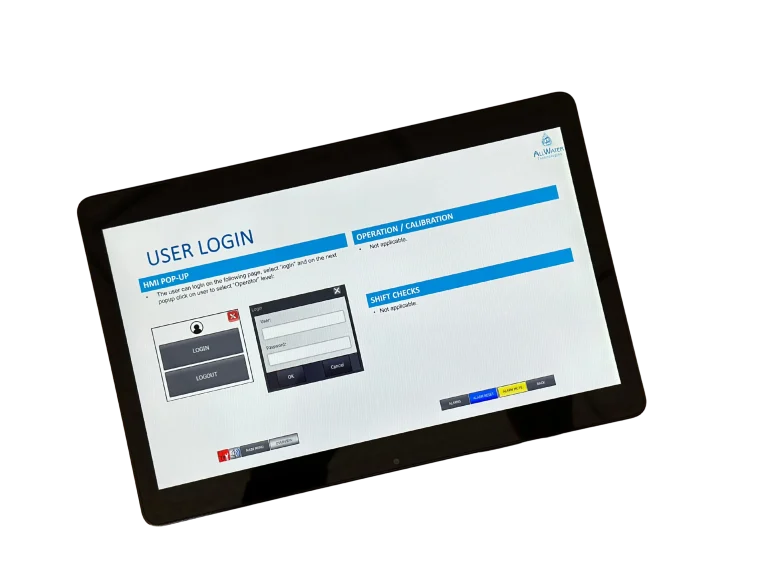

- Control panels for automated operation and safety interlocks

All systems are pre-tested, labelled, and documented to simplify installation and commissioning.

Technical Specifications

Typical Water Storage Tank Ranges:

- Volume: 50 – 30,000+ litres

- Wall thickness: Up to 20mm for structural stability

- Temperature range: -20°C to +60°C depending on material

- Pressure rating: Atmospheric (non-pressurised), can be vented or sealed

- Connections: BSP, PN10/16 flanges, or customised arrangements

- Optional insulation: 25mm or 50mm jackets

V-Notch Tank Specification Example:

- Tank capacity: 500L standard, custom sizes available

- Weir angle: 90° (standard), 60° optional

- Monitoring ports: 1–3 with IP65-rated sensor enclosures

- Access: Hinged inspection lid and sample tap

- Calibration: Flow tables provided or integrated with flow software

Applications Across Industry

Our industrial water tanks are used across a wide variety of sectors, including:

- Chemical manufacturing and blending

- Water treatment plants

- Pharmaceuticals and biotech

- Food and beverage production

- Agriculture and irrigation

- Power generation and CHP

- Laboratory and R&D facilities

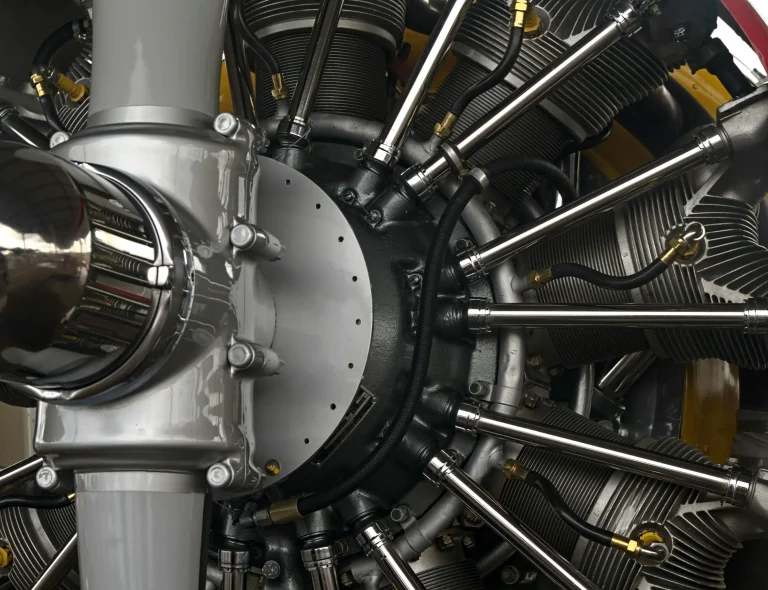

- Automotive and aerospace

Whether for process water, effluent monitoring, or chemical dosing, we can provide the right tank system for your needs.

Why Choose AllWater?

AllWater Technologies delivers more than just tanks. We offer complete engineering support, fast UK supply, and trusted long-term partnerships with manufacturers and clients.

Our Tank Supply Service Includes:

- Tank specification and selection advice

- 2D/3D drawings for approval and planning

- WRAS and compliance documentation

- Site delivery with offloading options

- Pipework kits and installation guidance

- Ongoing aftercare and spare parts

Our tanks are supported by decades of industry knowledge and designed to integrate smoothly with your broader water treatment system.

Committed to Excellence

"We have been very happy with AllWater’s professionalism and response times when we have needed help with the plant. The staff are all very helpful and knowledgeable and we are very satisfied with the service provided."

Jamie Davies

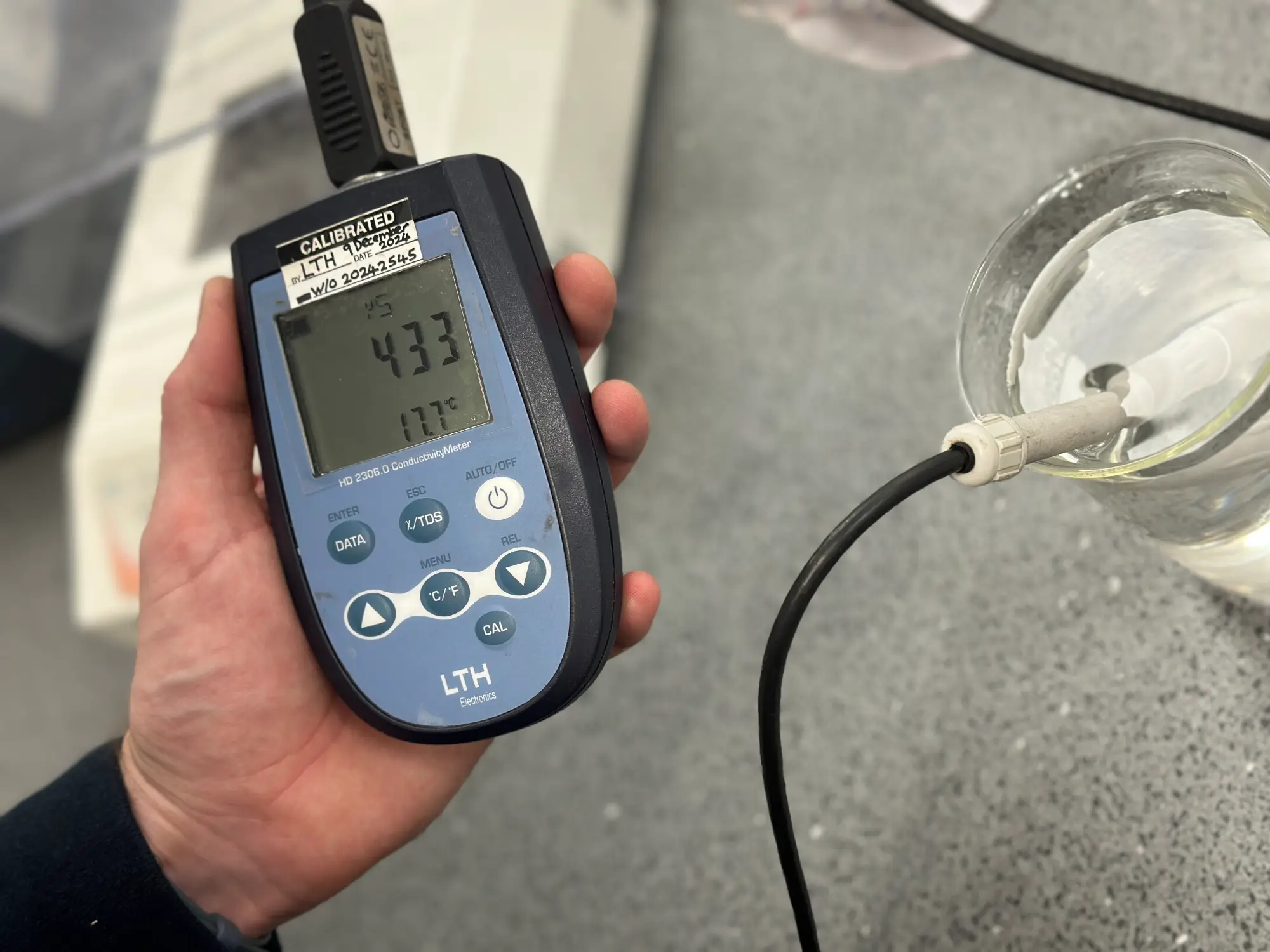

Turnspeed"We needed a DI plant that is capable of producing the processing water to serve our Chemical Process lines twelve rinse tanks, 24 hrs a day, 7 days a week at a max of 20.00 μS/cm. The water plant is now consistently cleaning the water to 1.00 μS/cm."

Steve Silk MBE

Marshall Aerospace"We have built a good relationship with AllWater and continue to enjoy service contracts with them. They know what they’re doing and we’re always happy with their service"

Andy Best

Production Director - Vertik-Al"AllWater Technologies installed their pure water system in our premises to replace our old system which went into retirement. The level of service and maintenance that AllWater are giving us will ensure that we get the quality of product and the length of service we are looking for out of our plant. Their level of service is excellent."

John Malone

excel gs ltd"Thank you for all your support. I have to say that I am really impressed with All Water approach to provide a really good service. Thank you again."

Radu Vitanescu

Liberty Engineering"AllWater have provided great service, specialist advice and an effective waste water treatment solution for our site."

Paul Pearcy

Warburtons"AllWater have always delivered us a great service and are equally competent maintaining existing kit or installing new. They’re friendly and reliable and, perhaps most importantly, trustworthy."

Phil Parkinson

Joseph Holt"AWT professional service allows our site to run with minimal downtime when unplanned breakdowns happen. AWT service is invaluable in maintaining our production lines throughout."

Adam Cook

Qsil"The person was very polite and explained everything in detail. Report was typed and easy to understand."

Richard Fox

London and Brighton Plating"We are more than satisfied with the level of service we receive from everyone at AWT. Excellent work, Thank you!"

Daniel Holden

Karas Plating"AllWater Technologies provide an exceptional level of knowledge and support, and we cannot fault their service and commitment. The team consistently exceed expectations and although others may offer a cheaper alternative, we have every confidence that they could not offer better!"

Eric Allen

Albumedix LTD"By using AWT we know that our plant and equipment is being maintained to the highest standard using the expertise and knowledge that we find second to none. When issues arise it is paramount that we can resolve these issues promptly; AWT are always there to support us."

Allen Staunton

Creganna Medical"Using All Water Technologies has been a breath of fresh air. Their attentive service from the first call through to delivery completion, has made the management of our water treatment plant very easy indeed. We wash over 2.5 million items of tableware for the event industry every year, working at some of the UK’s most prestigious events, so having peace of mind over our washing operation is essential. I would recommend AWT to anyone’"

Joe Nisbet

Jongor Hire"AWT offered Rimex a bespoke solution to our water softening and storage requirements. They took charge and managed the project efficiently and effectively from the very beginning. I am delighted with the outcome and I will continue to use AWT for preventative maintenance and any other future projects."

Daniel Meakin

Rimex Metals"All went very well with the plant being well finished, installation being of a high standard and all works being completed on time and to specification."

Dom Oughton

Optimum"We’ve been working with the AllWater team for eight years and they have always been attentive to our needs. AllWater redesigned our borehole system, transforming it into a robust and reliable plant whilst helping us improve water recovery and achieve significant water savings. We’ve depended on this system and their technical guidance for many years now and will continue to do so. Their work helps give us confidence and they are a partner we know we can trust."

Stephen Shields

Huntapac - Technical & Sustainability Director"At Butcombe, AllWater Technologies have been servicing the water treatment systems in our brewery for over 10 years. They are always at hand when we need them and all very friendly to deal with, and callouts are always made in a very timely manner. They have kept our beer flowing having never let us down. A great company with a quality reliable service."

Simon Court

Brewer - Butcombe Brewing Co.Ready for Support?

Unsure how to optimise water treatment for your industry? Our team is here to help. We’ll assess your requirements, design a solution, and provide the quality, reliability, and service you deserve. Reach out to discuss how we can help you achieve your operational goals.

Get in touch today to discuss your requirements.

Let’s keep your systems running at their best.

Water System Support: Frequently Asked Questions

WRAS approved tanks are certified for use with potable water. They help ensure your system meets UK regulations and avoids the risk of contamination.

Yes, we regularly supply tanks fitted with level sensors, flow meters, temperature probes, and data logging systems.

Yes, we offer single or double-skin bunded tanks to help contain leaks or spills in chemical and waste applications.

Absolutely. The weir angle and height can be specified to suit your flow measurement needs, and calibration tables are included.

We’ll assess your chemical, temperature, and pressure requirements and recommend the appropriate material with full technical backing.

Water Treatment Case Studies

Explore our case studies to see how AllWater Technologies has partnered with clients across various industries to design and deliver tailored water treatment solutions. Each project highlights our commitment to meeting exacting standards, solving unique challenges, and optimising water management processes to help our clients achieve their operational goals. Discover how our expertise and dedication to quality have made a real difference for businesses just like yours.

A Handful of our Valued Clients

Get in Touch with AllWater Technologies

We’re here to help with all your water treatment needs. Whether you have questions about our services, want to discuss a project, or need support, our team is ready to assist you. Fill out the form for general enquiries, or you are welcome to email direct or give us a call.

AllWater House

Unit 2,

Cheddar Business Park,

Wedmore Road,

Cheddar

BS27 3EB

Opening hours

Mon-Fri: 08:30-17:30 (GMT)