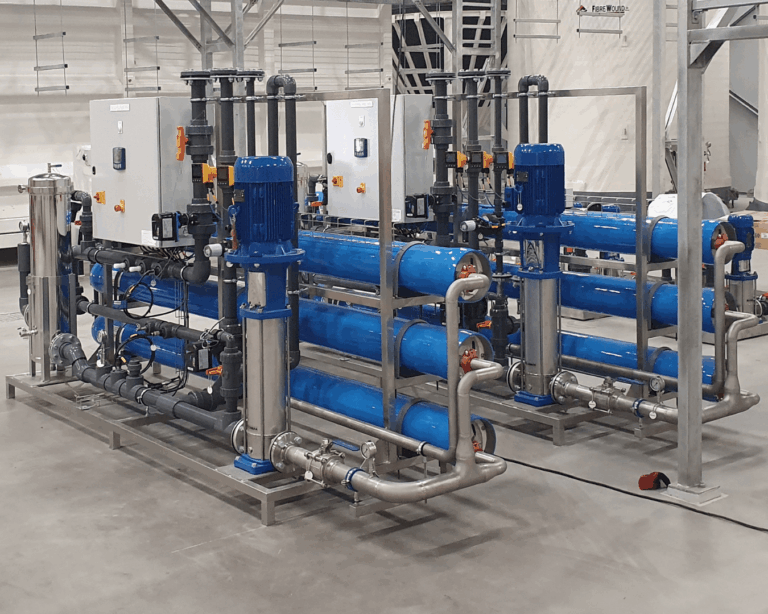

RO Vessels & Membranes

High-Performance Reverse Osmosis Components for Industrial Water Systems

AllWater Technologies supplies a complete range of RO vessels and membranes for industrial and commercial water treatment systems. Our pressure-rated membrane housings and high-rejection RO elements are sourced from leading manufacturers and specified to meet the rigorous demands of process water, clean water, and ultrapure applications.

Whether you are building a new RO system, replacing ageing components, or upgrading to higher-efficiency membranes, we offer reliable solutions backed by engineering support and fast UK-based delivery.

Reverse Osmosis Membrane Elements

At the heart of every RO system lies the reverse osmosis membrane—a semi-permeable element designed to remove dissolved salts, organic compounds, bacteria, and particulates from water under pressure. AllWater supplies a wide selection of RO membranes tailored to different feedwater types and performance requirements.

RO Membrane Types Supplied:

- Low Energy (LE) membranes

Operate at lower pressures (typically 6–10 bar), reducing energy costs while maintaining high rejection rates for clean or softened feedwaters. - High-Rejection membranes

Remove up to 99.7% of dissolved salts and organics, ideal for applications requiring ultrapure or low-conductivity water. - Brackish Water membranes (BWRO)

Designed for higher TDS levels, up to 8000 ppm, commonly used in industrial and inland desalination applications. - Fouling-resistant membranes

With wider flow channels and anti-fouling coatings, suited for surface water or wastewater reuse. - Hot water membranes

Suitable for CIP and sanitisation processes requiring operation at elevated temperatures.

RO membranes are available in all standard sizes (2.5″, 4″, and 8″ diameters) and are compatible with most commercial and industrial housings. Each element is supplied with performance data sheets and cleaning instructions.

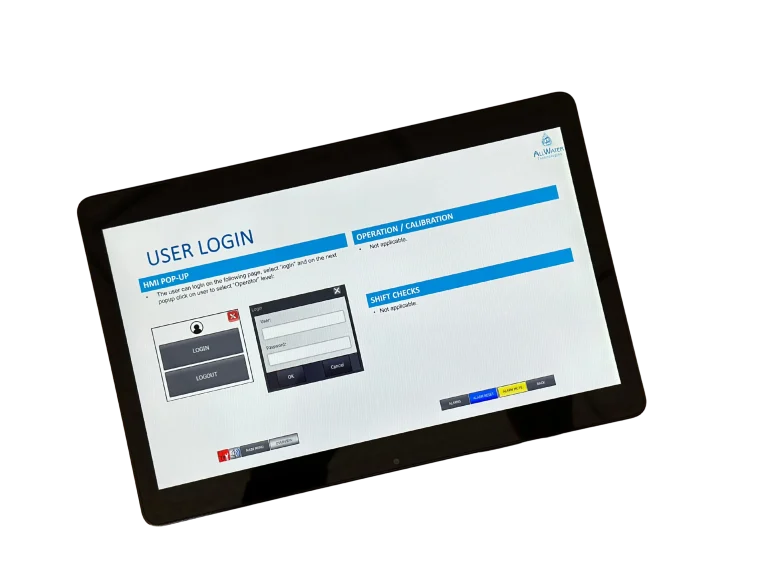

Our support includes

Telephone & remote diagnostics for rapid fault identification

System troubleshooting and root cause analysis

Planned service visits tailored to your production schedule

Guidance on optimisation, upgrades and retrofit options

Ongoing training and user support post-installation

On-site engineering support from qualified specialists

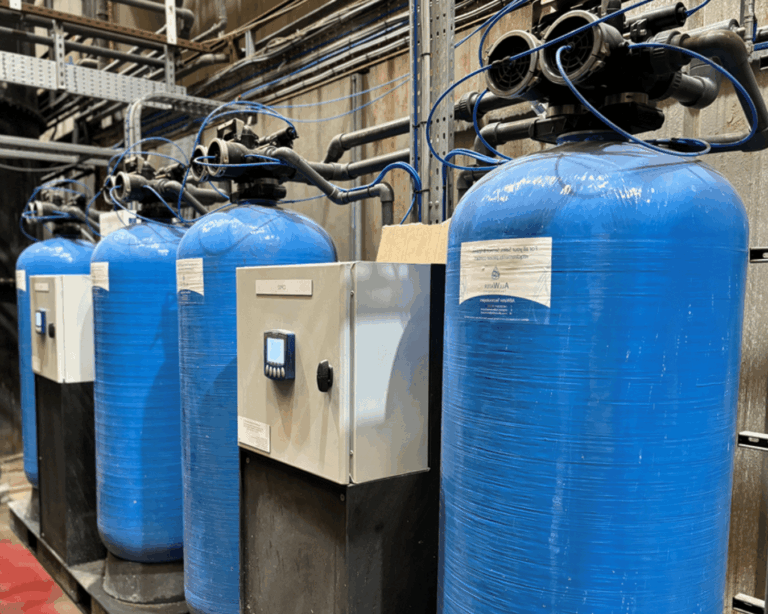

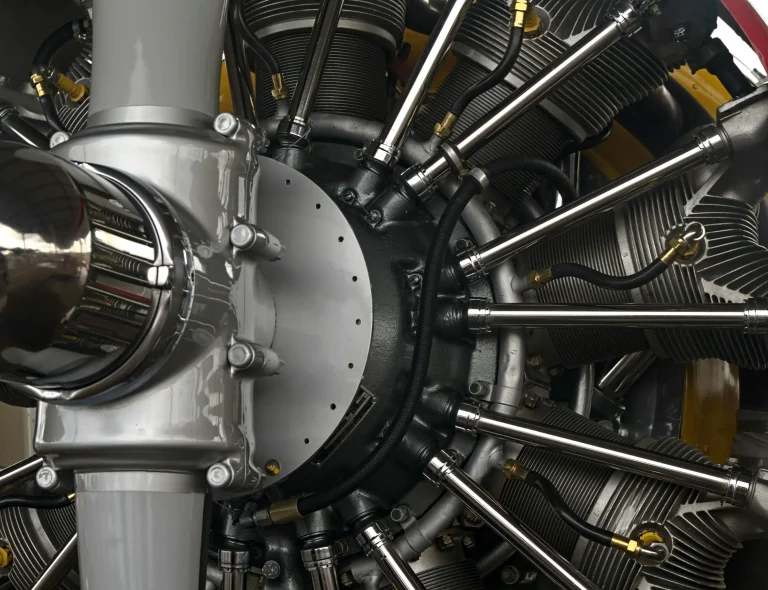

Pressure Vessels for RO Systems

Membranes are housed in pressure-rated enclosures called RO vessels or membrane housings. These are essential for safely operating the RO process, maintaining the required feed pressure, and facilitating easy membrane replacement.

Key Features of Our RO Vessels:

- Pressure ratings from 150 psi (10 bar) to 1200 psi (83 bar)

Supporting a wide range of RO applications, including seawater and high-pressure feed systems. - Construction materials

- FRP (Fibreglass Reinforced Plastic) with epoxy inner liners

Lightweight, corrosion-resistant, and cost-effective - Stainless steel housings (304 or 316)

Used in hygienic or high-temperature environments

- FRP (Fibreglass Reinforced Plastic) with epoxy inner liners

- Port configurations

Side-ported and end-ported options, with multi-port connectivity for banked membrane systems - Sizes supported

Standard lengths for 1, 2, 3, 4, 5, or 6 membrane elements per vessel

Compatible with 2.5″, 4″, and 8″ diameter membranes - Approvals and testing

Each vessel is hydro-tested and conforms to ASME and NSF requirements where applicable

We supply complete housings with end caps, adaptors, seals, interconnectors, and mounting hardware, ensuring ready integration into your RO skid.

Replacement Components and Accessories

To support long-term maintenance and upgrades, we also provide a full selection of replacement parts and RO accessories:

- End caps and thrust rings

- Interconnectors and couplers

- O-rings and seal kits

- Permeate ports and adaptors

- Membrane spacers and adapters

- Retaining clamps and straps

- Lubricants and puller tools

All components are carefully matched to the original manufacturer’s specifications to ensure leak-free, high-pressure operation.

Vessels:

- Material: FRP with PE/epoxy liner or stainless steel

- Design pressure: 150–1200 psi (10–83 bar)

- Test pressure: Typically 1.5x operating pressure

- Connection types: Victaulic, threaded, flanged, or clamp

- Mounting: Horizontal or vertical, with saddles or brackets

- Compliance: ASME, NSF, CE options available

Technical Specifications

Here are typical specifications for our RO vessels and membrane elements:

Membranes:

- Size: 2.5″, 4″, and 8″ diameter

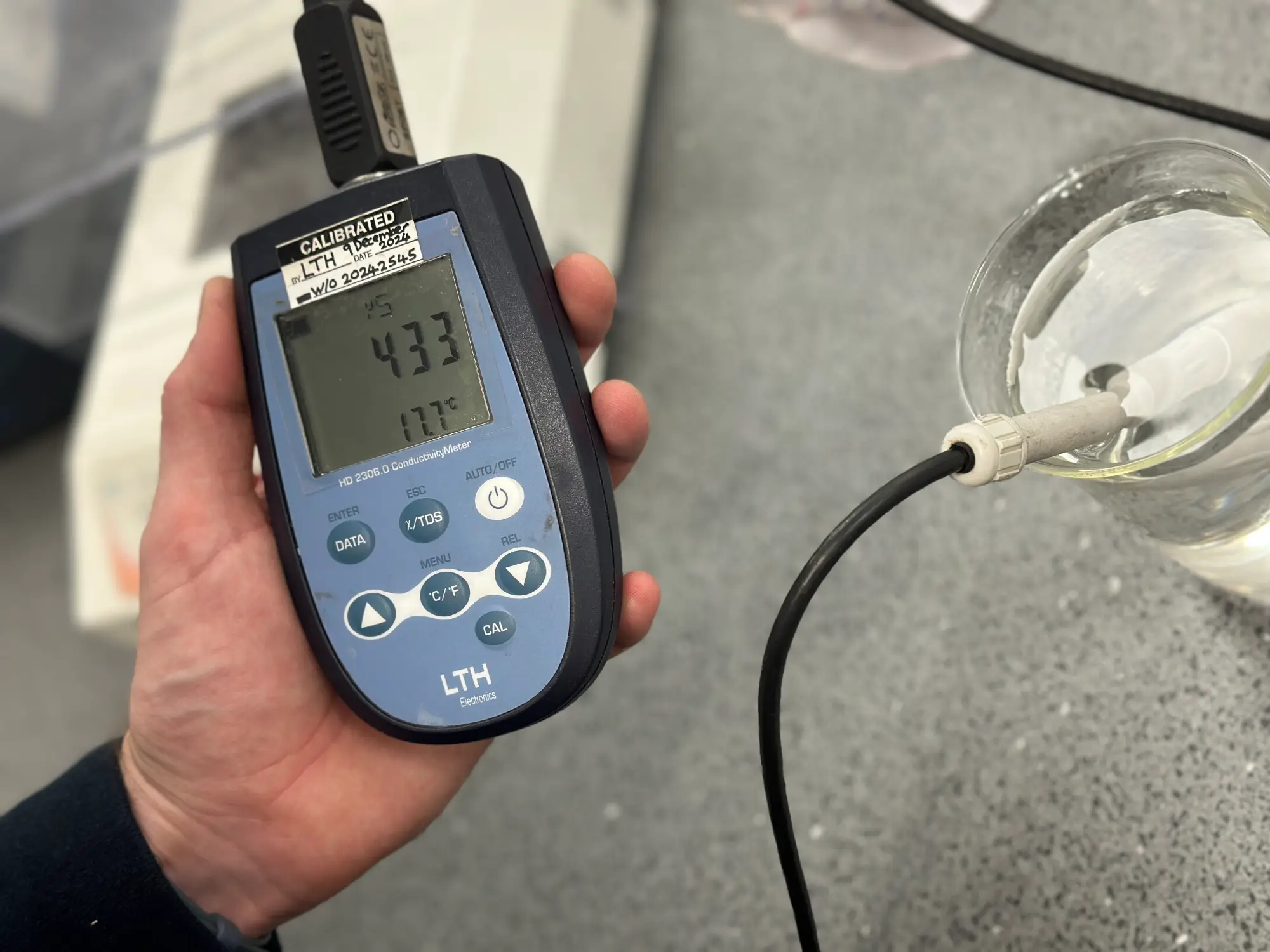

- Typical operating pressure: 6–15 bar (up to 83 bar for seawater membranes)

- Salt rejection: Up to 99.7% depending on type

- pH tolerance: 3–10 continuous; 2–11 for short-term CIP

- Temperature limit: Up to 45°C (70°C for hot water membranes)

- Flow rate: Ranges from 1,000 to 10,000+ L/day per element

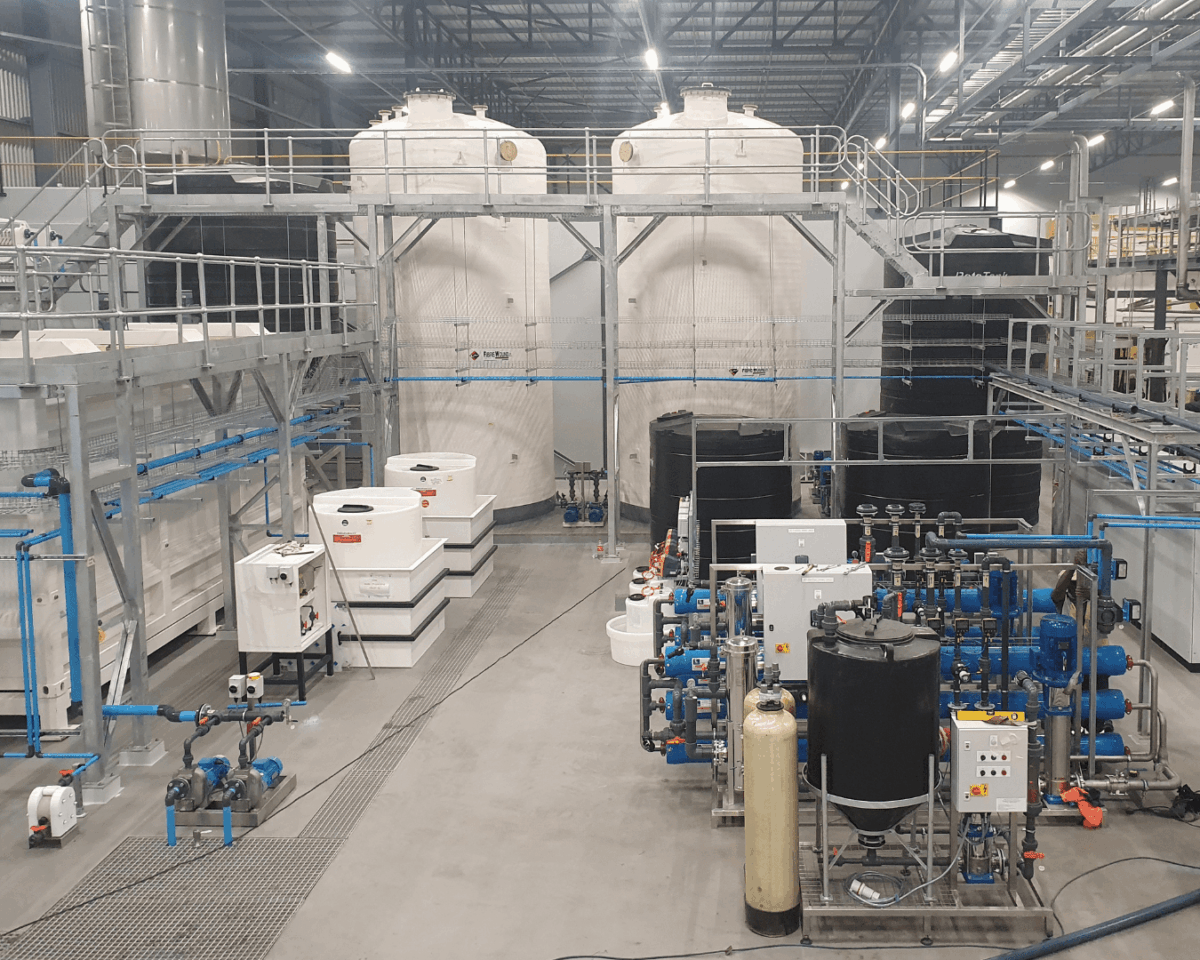

Applications for RO Membranes and Vessels

Our RO vessels and membranes are specified across a wide range of industrial, commercial, and specialist environments:

Common Sectors:

- Pharmaceutical water purification

- Boiler feed and condensate polishing

- Semiconductor and electronics manufacturing

- Food and beverage process water

- Laboratory and ultrapure water

- Automotive and surface finishing

- Glass, ceramics, and composites production

- Power generation and steam cycle support

- Desalination for inland or coastal installations

Our membranes can also be used as polishing stages for EDI or deionisation systems, ensuring extremely low conductivity and low TOC outputs.

Why Choose AllWater?

As experienced reverse osmosis membrane suppliers, AllWater Technologies offers more than just components—we deliver technical assurance and operational peace of mind.

Our RO supply service includes:

- Support with membrane selection and matching to feedwater analysis

- Vessel sizing and layout design for new systems

- Advice on pressure ratings and safe installation

- Cleaning protocols and CIP support

- Membrane life-cycle optimisation

- UK-based stock holding for fast turnaround

- Custom packaging and spares kits for maintenance teams

We also support full skid design and can fabricate pre-loaded membrane assemblies or install on site where required.

System Design & Retrofit Support

Whether you’re commissioning a new RO plant or retrofitting a single housing, our engineers can help you:

- Match membrane performance to production needs

- Specify vessels to suit flow, space, and pressure constraints

- Select cleaning-compatible components

- Ensure compatibility with pre-treatment and polishing stages

- Avoid common installation or fouling issues

- Plan membrane replacement schedules and cleaning routines

Let us streamline your procurement and ensure long-term reliability from your RO system.

Committed to Excellence

"We have been very happy with AllWater’s professionalism and response times when we have needed help with the plant. The staff are all very helpful and knowledgeable and we are very satisfied with the service provided."

Jamie Davies

Turnspeed"We needed a DI plant that is capable of producing the processing water to serve our Chemical Process lines twelve rinse tanks, 24 hrs a day, 7 days a week at a max of 20.00 μS/cm. The water plant is now consistently cleaning the water to 1.00 μS/cm."

Steve Silk MBE

Marshall Aerospace"We have built a good relationship with AllWater and continue to enjoy service contracts with them. They know what they’re doing and we’re always happy with their service"

Andy Best

Production Director - Vertik-Al"AllWater Technologies installed their pure water system in our premises to replace our old system which went into retirement. The level of service and maintenance that AllWater are giving us will ensure that we get the quality of product and the length of service we are looking for out of our plant. Their level of service is excellent."

John Malone

excel gs ltd"Thank you for all your support. I have to say that I am really impressed with All Water approach to provide a really good service. Thank you again."

Radu Vitanescu

Liberty Engineering"AllWater have provided great service, specialist advice and an effective waste water treatment solution for our site."

Paul Pearcy

Warburtons"AllWater have always delivered us a great service and are equally competent maintaining existing kit or installing new. They’re friendly and reliable and, perhaps most importantly, trustworthy."

Phil Parkinson

Joseph Holt"AWT professional service allows our site to run with minimal downtime when unplanned breakdowns happen. AWT service is invaluable in maintaining our production lines throughout."

Adam Cook

Qsil"The person was very polite and explained everything in detail. Report was typed and easy to understand."

Richard Fox

London and Brighton Plating"We are more than satisfied with the level of service we receive from everyone at AWT. Excellent work, Thank you!"

Daniel Holden

Karas Plating"AllWater Technologies provide an exceptional level of knowledge and support, and we cannot fault their service and commitment. The team consistently exceed expectations and although others may offer a cheaper alternative, we have every confidence that they could not offer better!"

Eric Allen

Albumedix LTD"By using AWT we know that our plant and equipment is being maintained to the highest standard using the expertise and knowledge that we find second to none. When issues arise it is paramount that we can resolve these issues promptly; AWT are always there to support us."

Allen Staunton

Creganna Medical"Using All Water Technologies has been a breath of fresh air. Their attentive service from the first call through to delivery completion, has made the management of our water treatment plant very easy indeed. We wash over 2.5 million items of tableware for the event industry every year, working at some of the UK’s most prestigious events, so having peace of mind over our washing operation is essential. I would recommend AWT to anyone’"

Joe Nisbet

Jongor Hire"AWT offered Rimex a bespoke solution to our water softening and storage requirements. They took charge and managed the project efficiently and effectively from the very beginning. I am delighted with the outcome and I will continue to use AWT for preventative maintenance and any other future projects."

Daniel Meakin

Rimex Metals"All went very well with the plant being well finished, installation being of a high standard and all works being completed on time and to specification."

Dom Oughton

Optimum"We’ve been working with the AllWater team for eight years and they have always been attentive to our needs. AllWater redesigned our borehole system, transforming it into a robust and reliable plant whilst helping us improve water recovery and achieve significant water savings. We’ve depended on this system and their technical guidance for many years now and will continue to do so. Their work helps give us confidence and they are a partner we know we can trust."

Stephen Shields

Huntapac - Technical & Sustainability Director"At Butcombe, AllWater Technologies have been servicing the water treatment systems in our brewery for over 10 years. They are always at hand when we need them and all very friendly to deal with, and callouts are always made in a very timely manner. They have kept our beer flowing having never let us down. A great company with a quality reliable service."

Simon Court

Brewer - Butcombe Brewing Co.Ready for Support?

Unsure how to optimise water treatment for your industry? Our team is here to help. We’ll assess your requirements, design a solution, and provide the quality, reliability, and service you deserve. Reach out to discuss how we can help you achieve your operational goals.

Get in touch today to discuss your requirements.

Let’s keep your systems running at their best.

Water System Support: Frequently Asked Questions

Most membranes last between 2–5 years depending on feedwater quality, fouling, and cleaning practices.

Often yes, as long as size and pressure compatibility are met. We can recommend drop-in replacements.

Yes. We offer high-pressure vessels rated up to 1200 psi suitable for SWRO applications.

You’ll need to match membrane size, pressure rating, port configuration, and material compatibility. We can guide you through selection.

Yes, we offer NSF/ANSI 61-certified housings for potable water systems upon request.

Water Treatment Case Studies

Explore our case studies to see how AllWater Technologies has partnered with clients across various industries to design and deliver tailored water treatment solutions. Each project highlights our commitment to meeting exacting standards, solving unique challenges, and optimising water management processes to help our clients achieve their operational goals. Discover how our expertise and dedication to quality have made a real difference for businesses just like yours.

A Handful of our Valued Clients

Get in Touch with AllWater Technologies

We’re here to help with all your water treatment needs. Whether you have questions about our services, want to discuss a project, or need support, our team is ready to assist you. Fill out the form for general enquiries, or you are welcome to email direct or give us a call.

AllWater House

Unit 2,

Cheddar Business Park,

Wedmore Road,

Cheddar

BS27 3EB

Opening hours

Mon-Fri: 08:30-17:30 (GMT)