Wastewater Treatment Solutions

Effluent treatment that delivers

compliance, sustainability, and cost control

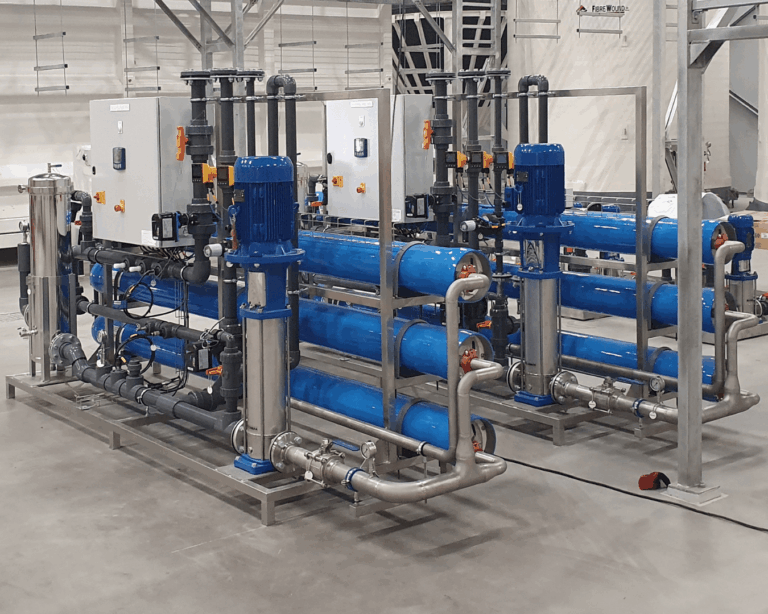

At AllWater Technologies, we design, build, and support advanced wastewater treatment solutions for a wide range of industrial and commercial applications. Whether you’re managing rinse water from metal finishing, tackling effluent from food processing, or seeking a sustainable water reuse system, we offer a bespoke approach to help you meet discharge regulations while reducing operational costs.

Our reputation as one of the UK’s trusted wastewater treatment plant manufacturers is built on engineering excellence, industry expertise, and a deep understanding of the evolving compliance landscape.

Why Choose AllWater for Wastewater Treatment?

When industrial processes generate wastewater, proper treatment is not optional—it’s essential. As environmental regulations tighten, businesses face mounting pressure to meet strict discharge consent levels, reduce pollutants, and minimise waste.

At AllWater Technologies, we offer:

- Customised industrial wastewater treatment systems

- Full-service design, manufacturing, and commissioning

- Expertise across chemical and physical treatment technologies

- Long-term system servicing and operator training

- Support for both new builds and retrofit or upgrade projects

Our goal is simple: to help you stay compliant, reduce costs, and make your operations more efficient and sustainable.

Our support includes

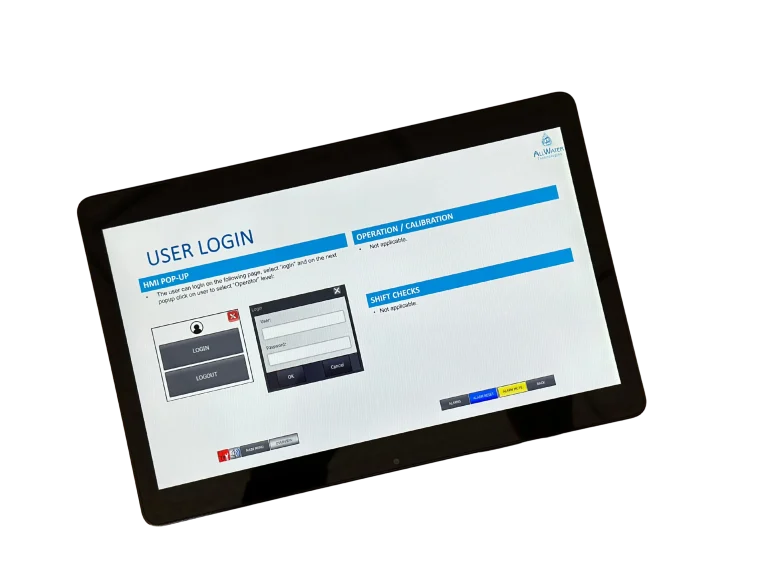

Telephone & remote diagnostics for rapid fault identification

System troubleshooting and root cause analysis

Planned service visits tailored to your production schedule

Guidance on optimisation, upgrades and retrofit options

Ongoing training and user support post-installation

On-site engineering support from qualified specialists

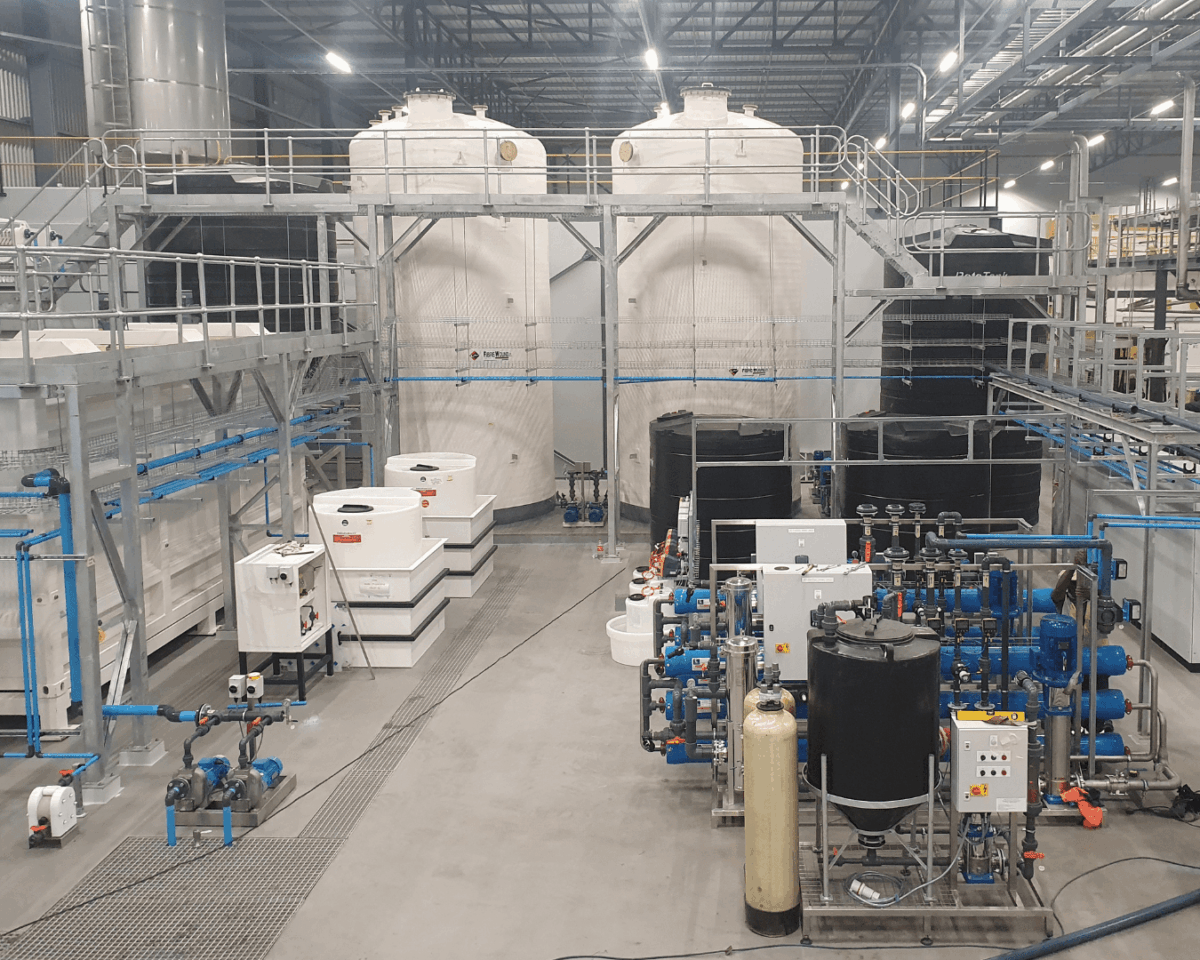

Industrial Wastewater Treatment Plant Design

We take a fully consultative approach to each project, ensuring the proposed solution aligns with your industry, processes, and wastewater characteristics. From standalone treatment tanks to complex industrial effluent treatment plant setups, we deliver fully engineered systems tailored to your business.

Typical system design considerations include:

- Inflow volume and variability

- Nature of contaminants (e.g. heavy metals, organics, suspended solids)

- Space constraints and integration into existing infrastructure

- Compliance with local discharge consents and trade effluent permits

- Energy efficiency and chemical optimisation

- Automation and remote monitoring requirements

Wastewater Treatment Technologies We Offer

Our team works with a wide array of technologies to build robust, cost-effective industrial waste water treatment plant systems, including:

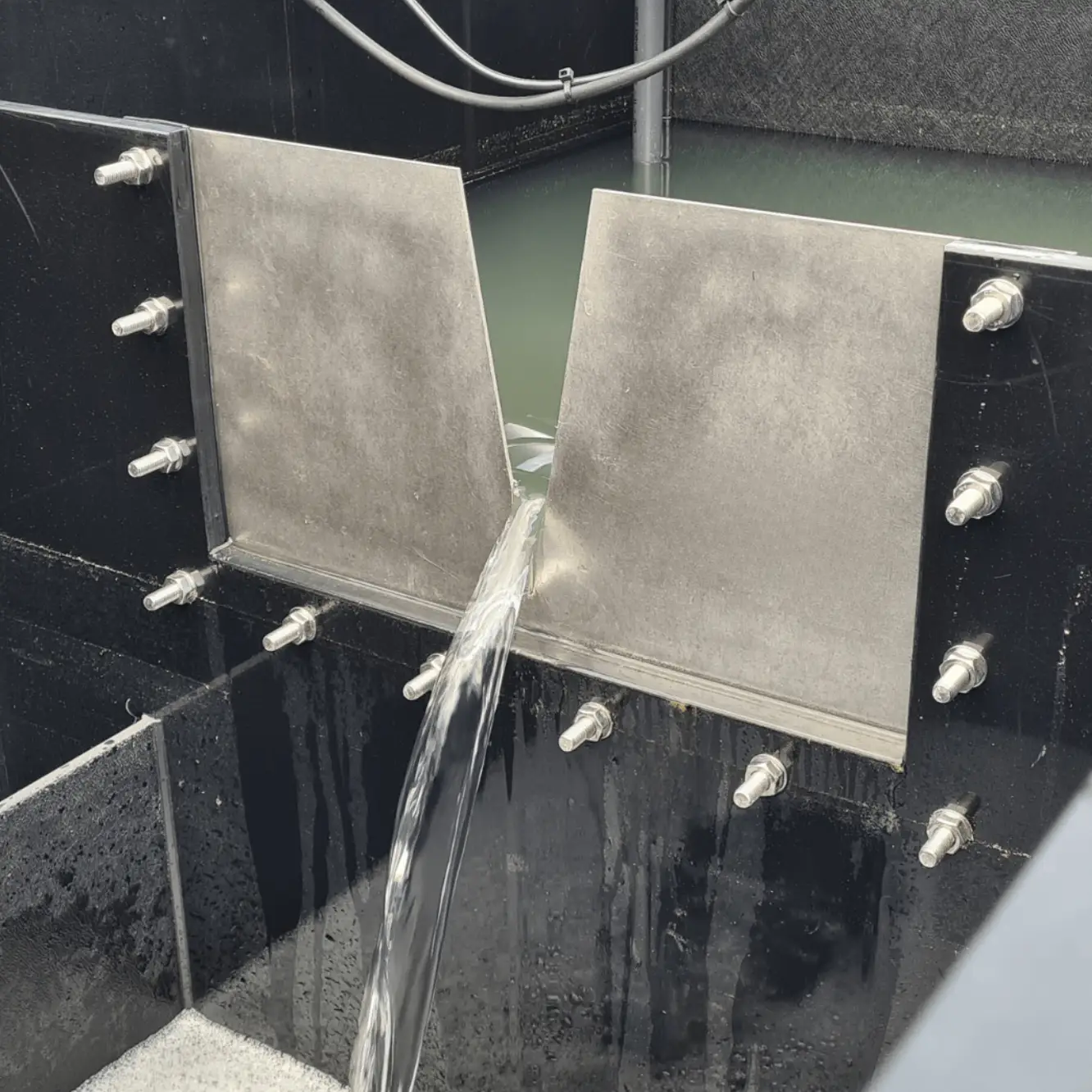

- pH correction and neutralisation

- Chromium reduction and cyanide oxidation

- Coagulation and flocculation processes

- Dosing skids with chemical storage and transfer

- Conventional settlement tanks and lamella clarifiers

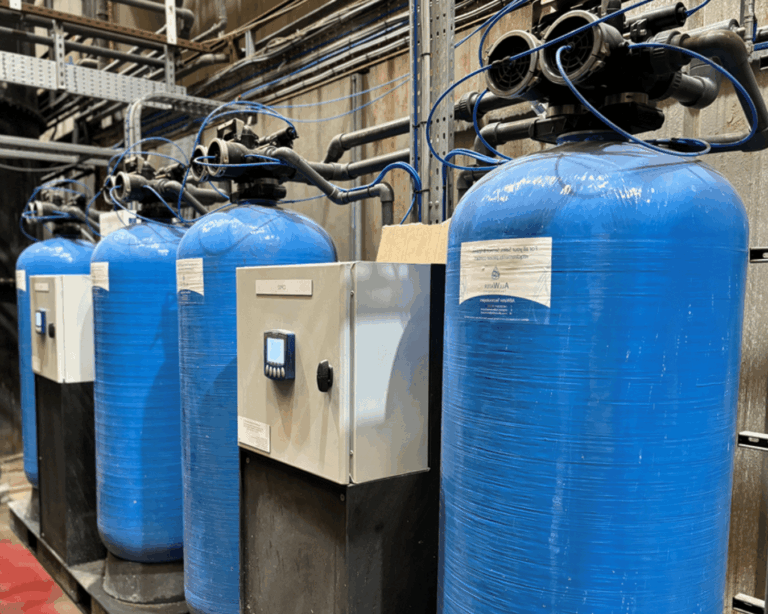

- Filtration systems (multimedia, sand, carbon)

- Oil separators and sludge dewatering presses

- Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF), Reverse Osmosis (RO)

- Ideal for water recycling and recovery

- Suitable for removing bacteria, organics, and salts

- Reduces wastewater volume

- Enables recovery of water for reuse

- Minimises off-site disposal costs

- Selective removal of heavy metals and dissolved ions

- Suitable for industries with metal contamination

- Often used for water polishing or recovery

Our team works with a wide array of technologies to build robust, cost-effective industrial waste water treatment plant systems, including:

Supporting Systems: Chemical Dosing and Handling

Effective wastewater treatment doesn’t stop at the main plant. That’s why we also supply:

- Chemical storage tanks (bunded, HDPE, or GRP)

- Dosing pumps and automated transfer systems

- Fume scrubbing and containment equipment

- PLC-controlled dosing sequences

These systems are fully integrated into your treatment plant and designed to reduce manual handling risks while improving dosing accuracy and chemical usage efficiency.

Water Recovery and Waste Minimisation

Disposing of wastewater is expensive. Wherever possible, we help clients implement water recovery strategies to minimise waste and improve sustainability.

This may involve:

- RO permeate reuse in rinse lines or process loops

- Filtrate recycling through UF or NF membranes

- Evaporation and condensate return for high-value applications

- Water balance reviews to identify waste reduction opportunities

Many of our clients have significantly reduced their trade effluent charges and off-site disposal costs by adopting wastewater recovery and reuse solutions.

Industry Applications

We have delivered wastewater solutions across a broad range of industries, including:

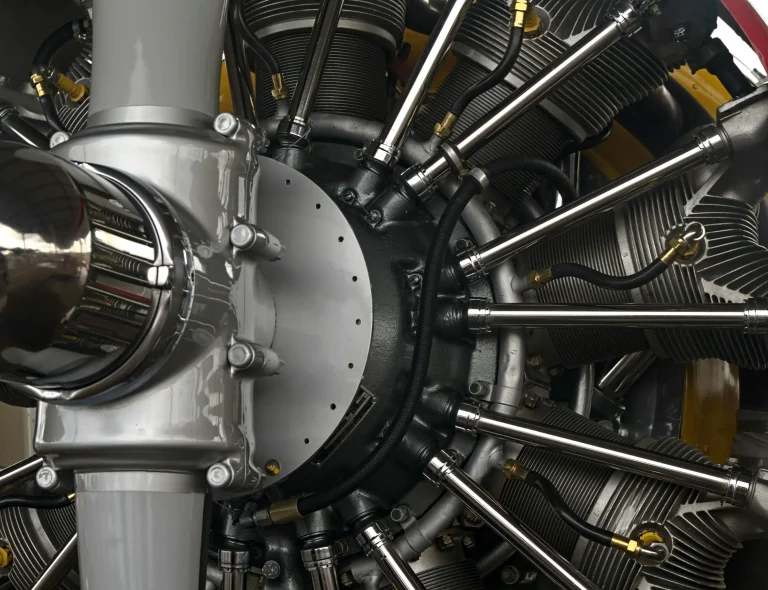

- Automotive & Aerospace – Surface treatment, paint lines, DI rinse

- Food & Beverage – High COD/BOD treatment, hygienic design

- Pharmaceuticals & Biotech – High-purity discharge and validation-ready systems

- Metal Finishing & Anodising – Heavy metal removal and neutralisation

- Chemical Processing – Complex effluent stream management

- Electronics & Microelectronics – Ultra-pure water recycling and metal recovery

Each project is supported by a dedicated project engineer, from feasibility and site survey through to commissioning and post-install support.

End-to-End Support from One of the UK’s Leading Effluent Treatment Companies

As an independent UK-based manufacturer, AllWater Technologies provides full in-house services:

- Feasibility studies and system design

- 3D modelling and project planning

- Fabrication, testing, and factory acceptance

- Mechanical and electrical installation

- Commissioning and operator training

- Ongoing service contracts and remote monitoring

We don’t just deliver a plant—we become your long-term wastewater partner.

Ready to explore a smarter wastewater treatment solution?

We’ll work with you to assess your current system, define your goals, and build a fully tailored solution that meets your environmental and operational needs.

Committed to Excellence

Frequently Asked Questions (FAQ)

An industrial wastewater treatment plant removes contaminants from wastewater produced during manufacturing and processing, ensuring compliance with environmental discharge regulations.

Effluent treatment plants (ETPs) treat wastewater from industrial processes to make it safe for discharge or reuse. They remove pollutants like heavy metals, organics, and chemicals.

Almost all manufacturing industries need wastewater treatment—including metal finishing, food and drink, chemicals, pharmaceuticals, and aerospace.

Yes. With the right design, many systems allow you to recover and reuse a significant percentage of your process water, reducing waste and operating costs.

Yes. AllWater Technologies designs and manufactures systems in-house in the UK. This ensures quality control, system customisation, and faster delivery.

"We have been very happy with AllWater’s professionalism and response times when we have needed help with the plant. The staff are all very helpful and knowledgeable and we are very satisfied with the service provided."

Jamie Davies

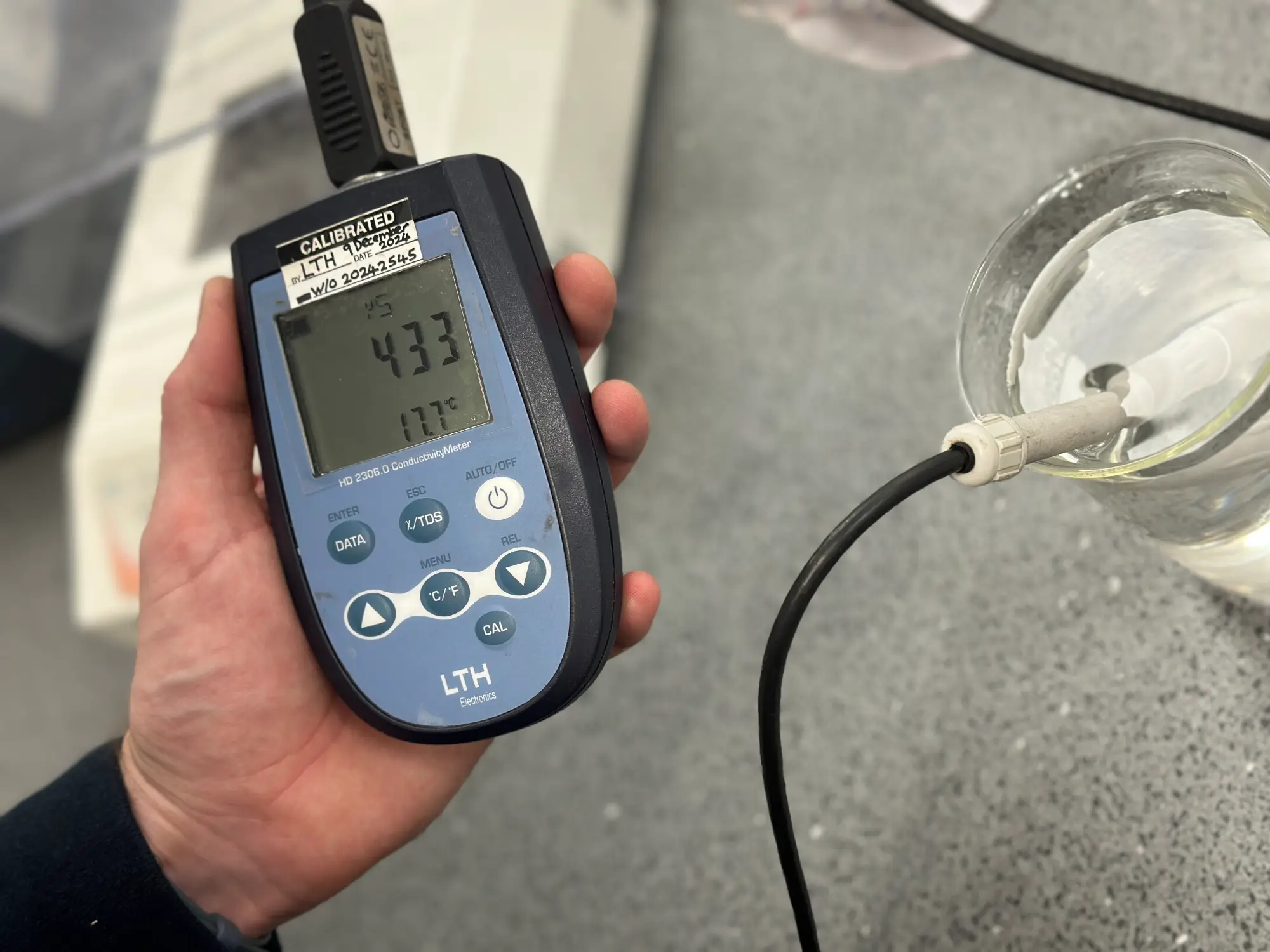

Turnspeed"We needed a DI plant that is capable of producing the processing water to serve our Chemical Process lines twelve rinse tanks, 24 hrs a day, 7 days a week at a max of 20.00 μS/cm. The water plant is now consistently cleaning the water to 1.00 μS/cm."

Steve Silk MBE

Marshall Aerospace"We have built a good relationship with AllWater and continue to enjoy service contracts with them. They know what they’re doing and we’re always happy with their service"

Andy Best

Production Director - Vertik-Al"AllWater Technologies installed their pure water system in our premises to replace our old system which went into retirement. The level of service and maintenance that AllWater are giving us will ensure that we get the quality of product and the length of service we are looking for out of our plant. Their level of service is excellent."

John Malone

excel gs ltd"Thank you for all your support. I have to say that I am really impressed with All Water approach to provide a really good service. Thank you again."

Radu Vitanescu

Liberty Engineering"AllWater have provided great service, specialist advice and an effective waste water treatment solution for our site."

Paul Pearcy

Warburtons"AllWater have always delivered us a great service and are equally competent maintaining existing kit or installing new. They’re friendly and reliable and, perhaps most importantly, trustworthy."

Phil Parkinson

Joseph Holt"AWT professional service allows our site to run with minimal downtime when unplanned breakdowns happen. AWT service is invaluable in maintaining our production lines throughout."

Adam Cook

Qsil"The person was very polite and explained everything in detail. Report was typed and easy to understand."

Richard Fox

London and Brighton Plating"We are more than satisfied with the level of service we receive from everyone at AWT. Excellent work, Thank you!"

Daniel Holden

Karas Plating"AllWater Technologies provide an exceptional level of knowledge and support, and we cannot fault their service and commitment. The team consistently exceed expectations and although others may offer a cheaper alternative, we have every confidence that they could not offer better!"

Eric Allen

Albumedix LTD"By using AWT we know that our plant and equipment is being maintained to the highest standard using the expertise and knowledge that we find second to none. When issues arise it is paramount that we can resolve these issues promptly; AWT are always there to support us."

Allen Staunton

Creganna Medical"Using All Water Technologies has been a breath of fresh air. Their attentive service from the first call through to delivery completion, has made the management of our water treatment plant very easy indeed. We wash over 2.5 million items of tableware for the event industry every year, working at some of the UK’s most prestigious events, so having peace of mind over our washing operation is essential. I would recommend AWT to anyone’"

Joe Nisbet

Jongor Hire"AWT offered Rimex a bespoke solution to our water softening and storage requirements. They took charge and managed the project efficiently and effectively from the very beginning. I am delighted with the outcome and I will continue to use AWT for preventative maintenance and any other future projects."

Daniel Meakin

Rimex Metals"All went very well with the plant being well finished, installation being of a high standard and all works being completed on time and to specification."

Dom Oughton

Optimum"We’ve been working with the AllWater team for eight years and they have always been attentive to our needs. AllWater redesigned our borehole system, transforming it into a robust and reliable plant whilst helping us improve water recovery and achieve significant water savings. We’ve depended on this system and their technical guidance for many years now and will continue to do so. Their work helps give us confidence and they are a partner we know we can trust."

Stephen Shields

Huntapac - Technical & Sustainability Director"At Butcombe, AllWater Technologies have been servicing the water treatment systems in our brewery for over 10 years. They are always at hand when we need them and all very friendly to deal with, and callouts are always made in a very timely manner. They have kept our beer flowing having never let us down. A great company with a quality reliable service."

Simon Court

Brewer - Butcombe Brewing Co.Ready for Support?

Unsure how to optimise water treatment for your industry? Our team is here to help. We’ll assess your requirements, design a solution, and provide the quality, reliability, and service you deserve. Reach out to discuss how we can help you achieve your operational goals.

Get in touch today to discuss your requirements.

Let’s keep your systems running at their best.

Water Treatment Case Studies

Explore our case studies to see how AllWater Technologies has partnered with clients across various industries to design and deliver tailored water treatment solutions. Each project highlights our commitment to meeting exacting standards, solving unique challenges, and optimising water management processes to help our clients achieve their operational goals. Discover how our expertise and dedication to quality have made a real difference for businesses just like yours.

A Handful of our Valued Clients

Get in Touch with AllWater Technologies

We’re here to help with all your water treatment needs. Whether you have questions about our services, want to discuss a project, or need support, our team is ready to assist you. Fill out the form for general enquiries, or you are welcome to email direct or give us a call.

AllWater House

Unit 2,

Cheddar Business Park,

Wedmore Road,

Cheddar

BS27 3EB

Opening hours

Mon-Fri: 08:30-17:30 (GMT)