Vertik-Al, a leading provider of vertical and horizontal Aluminium powder coating for the architectural Aluminium industry, faced a critical challenge when European regulations (REACH) prohibited the use of Hexavalent Chromium in their pre-treatment process. To comply with regulations while maintaining consistent production efficiency, Vertik-Al needed a reliable water supply with stringent quality requirements.

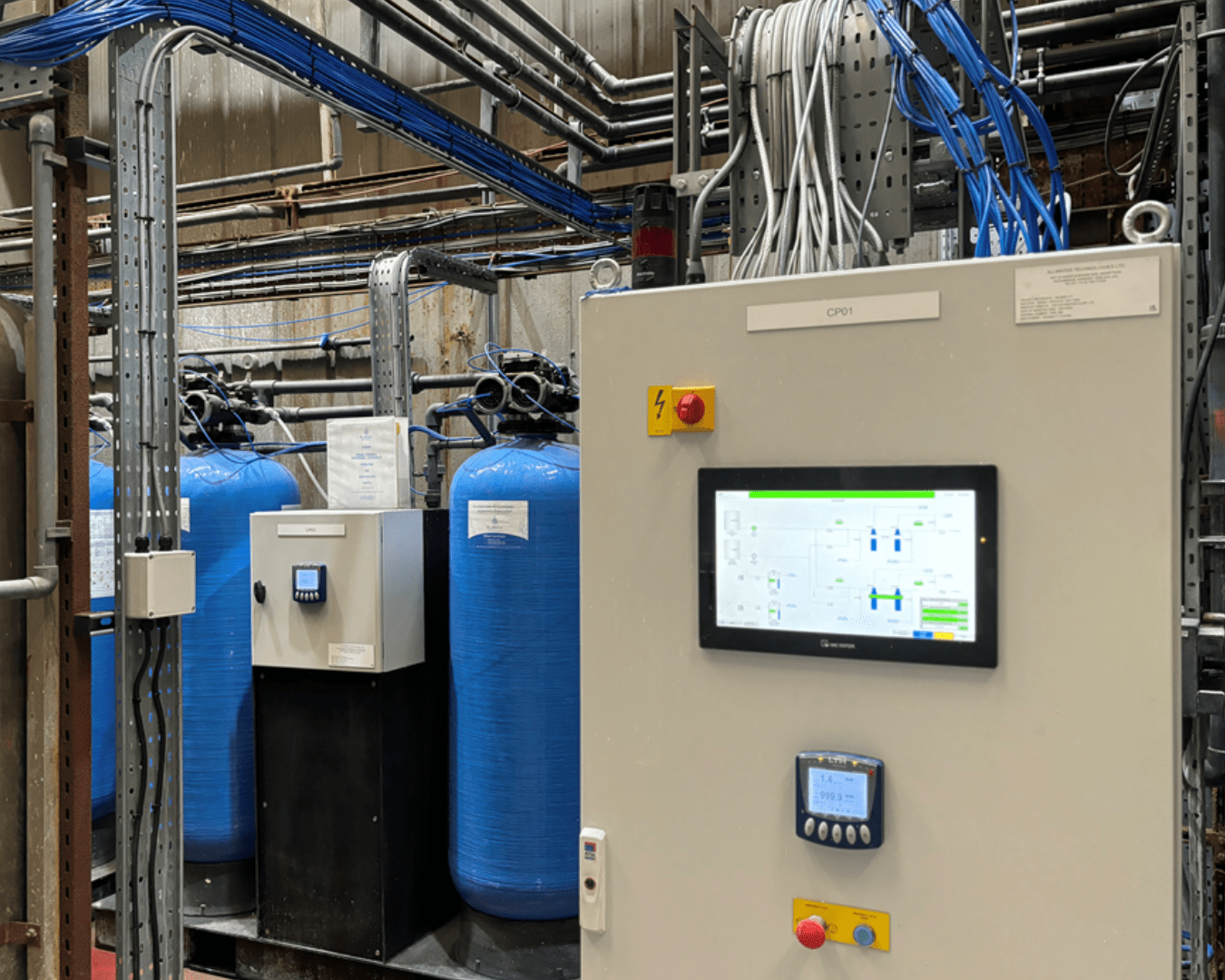

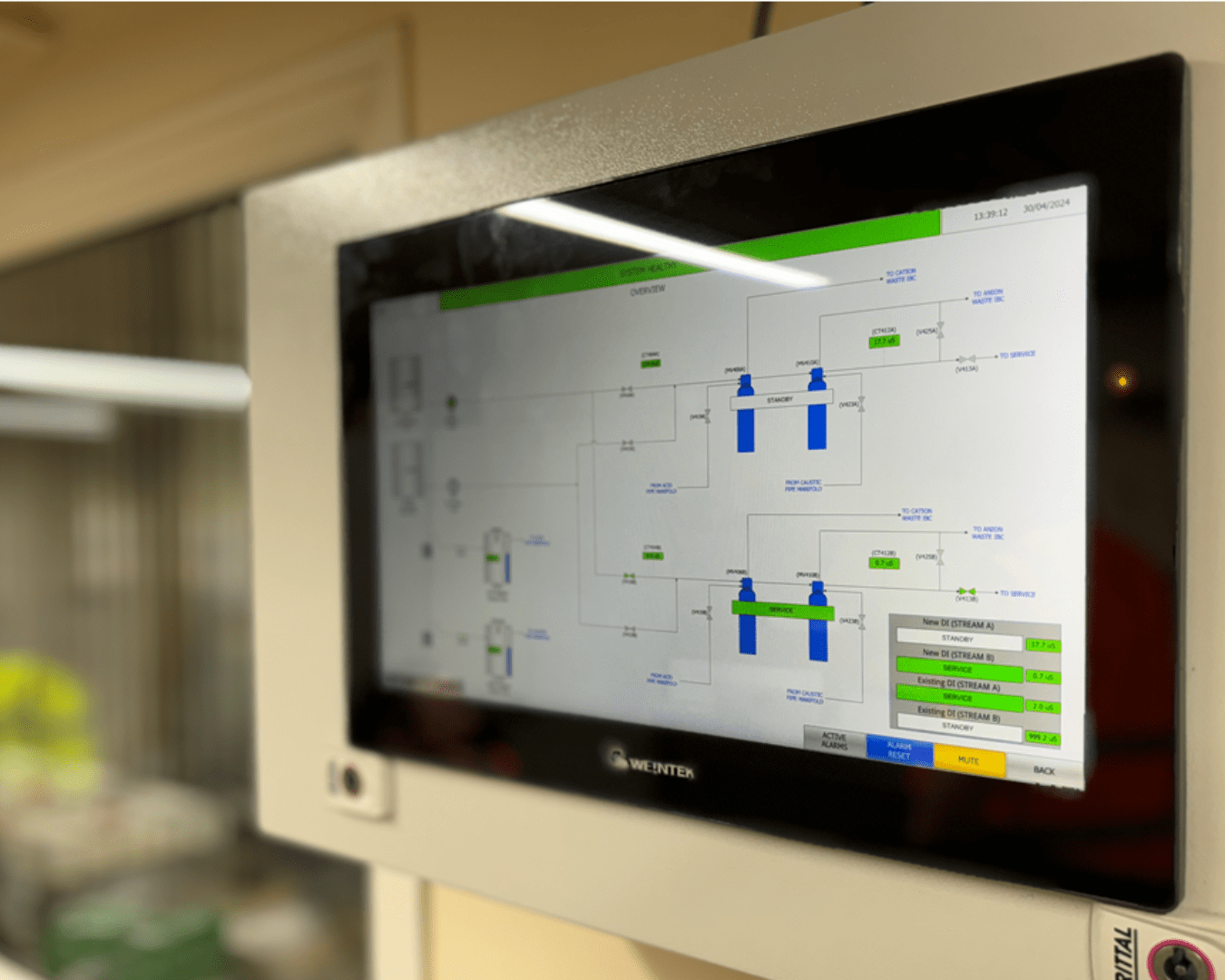

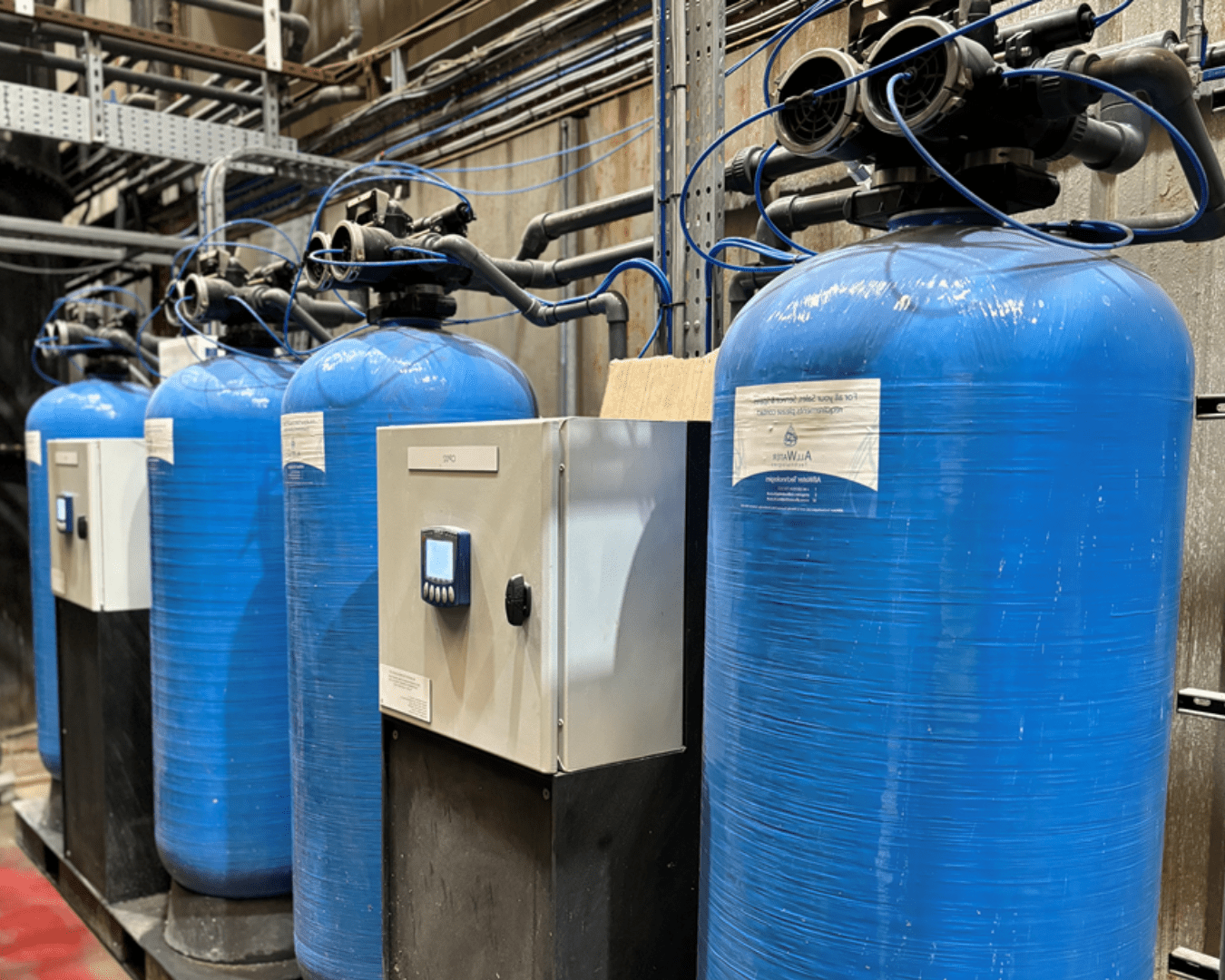

The transition from a Hexavalent Chromium to a Chromium-free process required a large volume of water with a quality level below 30 μS/cm to ensure effective pre-treatment. Restrictive space at VertikAl’s facility posed significant hurdles for installing the required water treatment systems. Additionally, maintaining uninterrupted production during the transition was crucial for Vertik-Al to meet customer demands and ensure operational continuity.

The integrated water treatment system provided by AllWater enabled Vertik-Al to meet stringent purity standards for Chromium-free processes, ensuring compliance with REACH regulatory requirements whilst enhancing operational efficiency. Despite space constraints and existing infrastructure limitations, the seamless integration of the new water treatment system allowed Vertik-Al to maintain uninterrupted production, eliminating downtime and sustaining productivity. By leveraging AllWater’s expertise and innovative solutions, Vertik-Al successfully navigated the transition to Chromium-free manufacturing processes, demonstrating a commitment to regulatory compliance and operational excellence.

"We have been very happy with AllWater’s professionalism and response times when we have needed help with the plant. The staff are all very helpful and knowledgeable and we are very satisfied with the service provided."

"We needed a DI plant that is capable of producing the processing water to serve our Chemical Process lines twelve rinse tanks, 24 hrs a day, 7 days a week at a max of 20.00 μS/cm. The water plant is now consistently cleaning the water to 1.00 μS/cm."

"We have built a good relationship with AllWater and continue to enjoy service contracts with them. They know what they’re doing and we’re always happy with their service"

"AllWater Technologies installed their pure water system in our premises to replace our old system which went into retirement. The level of service and maintenance that AllWater are giving us will ensure that we get the quality of product and the length of service we are looking for out of our plant. Their level of service is excellent."

"Thank you for all your support. I have to say that I am really impressed with All Water approach to provide a really good service. Thank you again."

"AllWater have provided great service, specialist advice and an effective waste water treatment solution for our site."

"AllWater have always delivered us a great service and are equally competent maintaining existing kit or installing new. They’re friendly and reliable and, perhaps most importantly, trustworthy."

"AWT professional service allows our site to run with minimal downtime when unplanned breakdowns happen. AWT service is invaluable in maintaining our production lines throughout."

"The person was very polite and explained everything in detail. Report was typed and easy to understand."

"We are more than satisfied with the level of service we receive from everyone at AWT. Excellent work, Thank you!"

"AllWater Technologies provide an exceptional level of knowledge and support, and we cannot fault their service and commitment. The team consistently exceed expectations and although others may offer a cheaper alternative, we have every confidence that they could not offer better!"

"By using AWT we know that our plant and equipment is being maintained to the highest standard using the expertise and knowledge that we find second to none. When issues arise it is paramount that we can resolve these issues promptly; AWT are always there to support us."

"Using All Water Technologies has been a breath of fresh air. Their attentive service from the first call through to delivery completion, has made the management of our water treatment plant very easy indeed. We wash over 2.5 million items of tableware for the event industry every year, working at some of the UK’s most prestigious events, so having peace of mind over our washing operation is essential. I would recommend AWT to anyone’"

"AWT offered Rimex a bespoke solution to our water softening and storage requirements. They took charge and managed the project efficiently and effectively from the very beginning. I am delighted with the outcome and I will continue to use AWT for preventative maintenance and any other future projects."

"All went very well with the plant being well finished, installation being of a high standard and all works being completed on time and to specification."

"We’ve been working with the AllWater team for eight years and they have always been attentive to our needs. AllWater redesigned our borehole system, transforming it into a robust and reliable plant whilst helping us improve water recovery and achieve significant water savings. We’ve depended on this system and their technical guidance for many years now and will continue to do so. Their work helps give us confidence and they are a partner we know we can trust."

"At Butcombe, AllWater Technologies have been servicing the water treatment systems in our brewery for over 10 years. They are always at hand when we need them and all very friendly to deal with, and callouts are always made in a very timely manner. They have kept our beer flowing having never let us down. A great company with a quality reliable service."

We’re here to help with all your water treatment needs. Whether you have questions about our services, want to discuss a project, or need support, our team is ready to assist you. Fill out the form for general enquiries, or you are welcome to email direct or give us a call.

Unit 2,

Cheddar Business Park,

Wedmore Road,

Cheddar

BS27 3EB

Mon-Fri: 08:30-17:30 (GMT)